Jet Mill Technology delivers precise, contamination-free particle size reduction for advanced material processing. With the continuous development of modern science and technology, people’s demand for ceramic materials is getting higher and higher. As a new type of powder preparation technology, air jet milling technology has gradually been applied to the preparation of ceramic materials. This article will discuss the basic principles of air jet mill. It will analyze the advantages and disadvantages of this technology. Discuss the application and development trend in the preparation of ceramic materials.

The basic principle, advantages and disadvantages of air jet mill

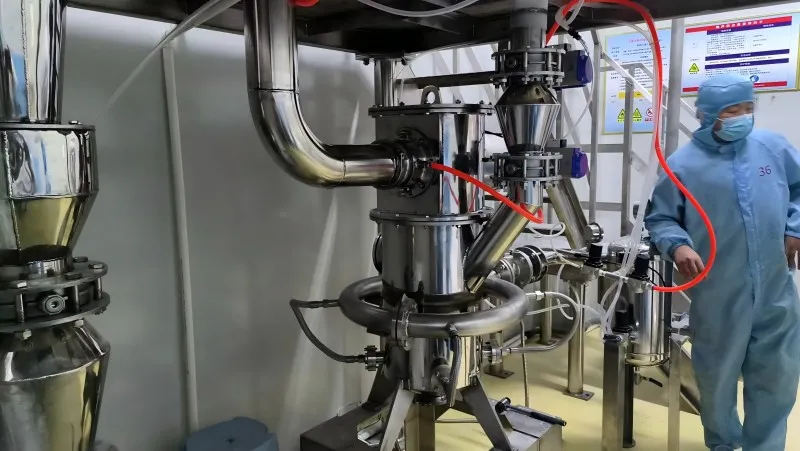

Airflow mill is a powder preparation technology that uses high-speed airflow to collide and grind materials. Its basic principle is to feed the material into the airflow mill. Then the material are dispersed, ground and mixed the material through the impact and shear force of high-speed gas. Thus we can obtain the powder as required. Compared with the traditional mechanical grinding method, the airflow mill has the following advantages:

- ① Uniform particle size distribution: During the grinding process , the material is impacted and sheared by the high-speed airflow. Particles collide and rub against each other in the process. This ensures a more consistent particle size distribution.

- ② High powder quality: During the grinding process, forces applied to materials are more uniform. It is not easy to produce excessive wear and heat loss, thereby obtaining a higher quality powder.

- ③ High production efficiency: The airflow mill has high production efficiency, high degree of automation and low energy consumption.

However, the airflow mill also has some shortcomings, high gas consumption and significant noise issues. Therefore, these problems need to be paid attention to in practical applications.

Application and development trend of jet mill in preparation of ceramic materials

The application of airflow milling technology in the preparation of ceramic materials mainly includes the following aspects:

- ① Preparation of ceramic powders: airflow milling can be used for the preparation of ceramic powders, such as zirconium oxide, aluminum oxide, silicate, etc.

- ② Preparation of ceramic coatings: airflow milling can be used for the preparation of ceramic coatings, such as coatings on the surface of ceramic materials, etc.

- ③ Preparation of ceramic composite materials: airflow milling can be used for the preparation of ceramic composite materials, such as ceramic-based composite materials, etc.

With the continuous advancement of science and technology, airflow milling technology is also constantly developing and improving. In the future, In the future, air jet milling technology will see broader applications in ceramic material preparation. Additionally, continuous innovations and advancements in this field are expected.