In the pharmaceutical industry, ultrafine pulverization generally has the following characteristics

- Small particle size, concentrated and uniform distribution, saving raw materials;

- Adiabatic expansion of low-temperature and high-pressure air will absorb the heat generated by the collision of materials, will not overheat locally, and retain the biologically active ingredients of the drug, which is conducive to making the required high-quality products;

- Simple quick disassembly and assembly structure, which is conducive to cleaning and replacing material varieties.

Generally, the size of the particles is about 100 microns, and they are ultra-finely pulverized to several microns. After ultra-micro processing, the surface area of the particles increases, and their dispersibility, adsorption capacity, surface activity, etc. have comprehensive changes. It is of great significance for improving the efficacy and saving the dosage.

We can provide processes and equipment that meet the following performance indicators

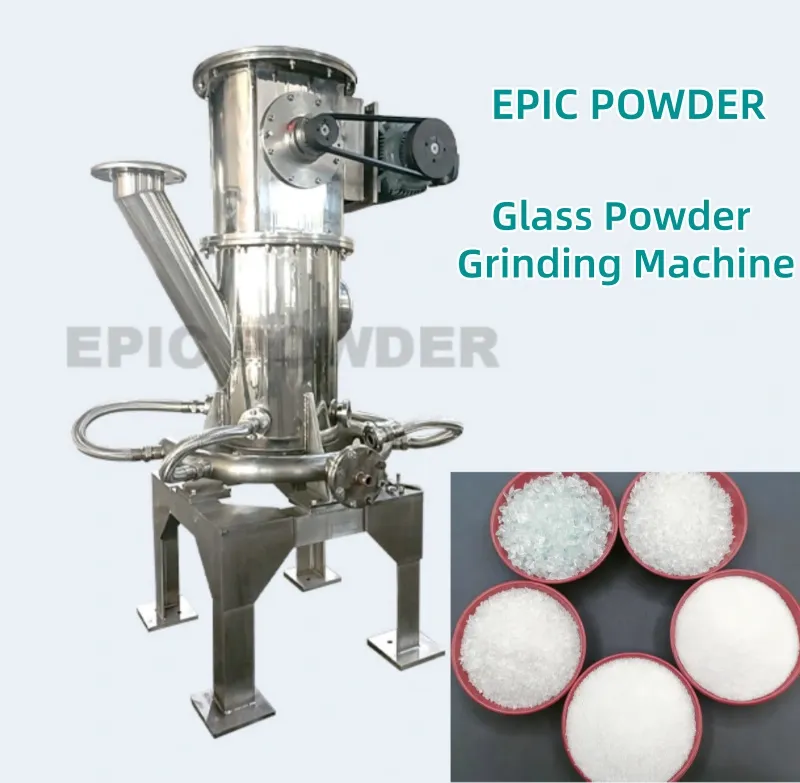

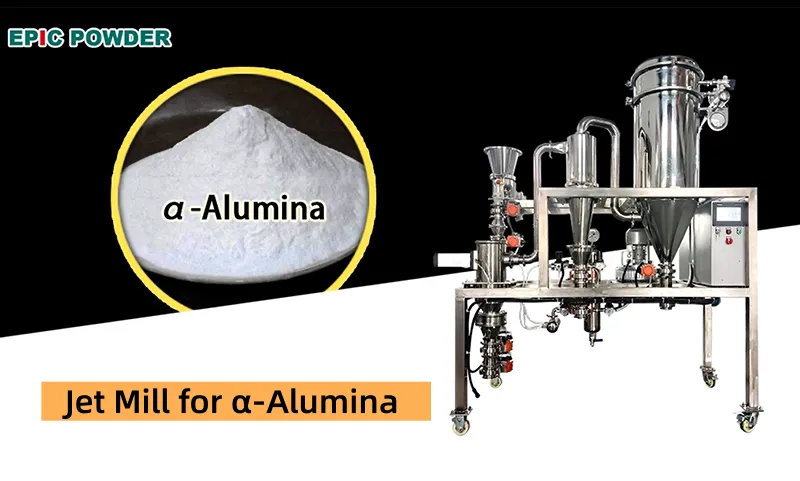

Jet Mill

Suitable for grinding materials with high hardness, high purity and high added value.

Air Classifying Mill

Integration of grinding and classifying

Spiral Jet Mill

On-line cleaning (CIP) and on-line sterilization(SIP)design is optional.

- Full ceramic protection, increased amount of metal <20ppb.

- The physical shape of the particles is stable, the particle size is uniform, and has good dispersibility, and does not cause agglomeration or precipitation.

- Simple quick disassembly and assembly structure, which is conducive to cleaning and replacing materials.

- Low residue, low pollution, less impurities.

- Jet mill can be used instead of impact mill for production, with higher safety and finer particle size.