Powder Metallurgy

With the development of industrial modernization in our country, powder metallurgy is widely used in various fields such as military, aerospace, and civilian. Due to the complexity of metallurgical powder production, there are strict requirements for enterprises in terms of grinding technology, particle requirements, safety and explosion prevention, product purity, control of oxygen and moisture, and collection system efficiency. There are also high screening standards for related equipment and processes.

We can provide processes and equipment that meet the following performance indicators

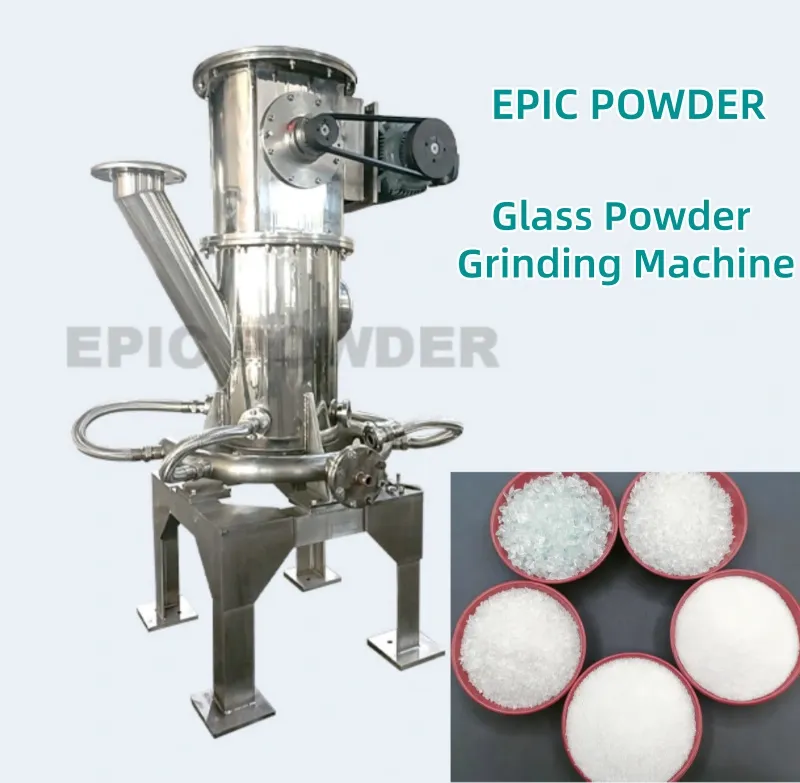

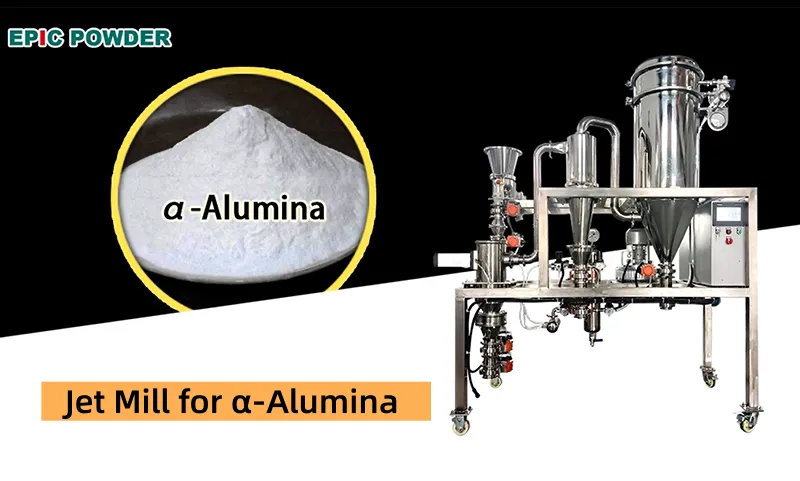

- According to the characteristics of the materials, various crushing technologies such as airflow crushing, impact crushing, ball milling crushing, roller pressing crushing, shear crushing, etc. are flexibly used to selectively crush the materials to the micrometer or submicron level.

- For metallurgical powders after grinding or materials after atomization, the particle size distribution between 1 micron and 100 microns can be adjusted by a classifier to achieve different distribution states such as narrow particle size distribution or normal particle size distribution.

- Most metallurgical powders have the characteristics of being flammable and explosive in production processes such as grinding, grading, and conveying. In response to this characteristic, Elpai adopts automated and intelligent monitoring and control methods and inert gas circulation protection systems in the powder process, ensuring the safety and controllability of the production process through multiple measures.