Strict particle size distribution requirements intensify the growing needs for the classification of ultrafine powders. High-capacity, energy-efficient ultrafine classifiers are prioritized for industrial applications. Precise classification of ultrafine powders ensures optimized product performance. Intelligent classification systems support material innovation and production upgrades.

Classification of ultrafine powders

Broadly speaking: Classification involves dividing particles into different groups based on properties such as particle size, density, color, shape, chemical composition, magnetism, and radioactivity.

Narrowly speaking: classification refers to the separation of particles based on their different particle sizes, where centrifugal force, gravity, inertia, and other forces in a medium (typically air or water) cause particles to follow different movement trajectories, thus achieving classification of particles with different sizes.

Ultrafine Powder Classification Principles

- Centrifugal Classification Principle

- Inertial Classification Principle

- Rapid Classification Principle

- Vacuum Classification Principle

- Gravitational Field Classification Principle

- Wall Effect Classification Theory

Commonly used gravity classification and centrifugal classification principles are applied in various types of classifiers, each suited to different processing needs.

The significance of Classification of ultrafine powders

On one hand, it controls the product particle size to remain within the desired distribution range. On the other hand, it ensures that particles in the mixture that have reached the required size are separated in time, while coarse particles are returned for regrinding to improve grinding efficiency and reduce energy consumption.

Factors affecting classification performance

Structural parameters: rotor structure, rotor blades, guide vanes, pre-dispersion structure, classification chamber space.

Operation parameters: rotation speed, air volume, feeding speed.

Material parameters: material fineness, material moisture content, particle hardness.

Ultrafine Classifier equipment

Horizontal Air Classifier -HTS

This air classifiers series HTS has been developed especially for ultra fine products from 2micron to 120micron.The main point of its development was to achieve a high fineness of the end product. A good sharpness, high eficiency and low specific energyconsumption with highest fines output were the guideline for this classifier design too.

The classifying wheel of the series HTS is especially designed for highest srength during production, The wheel is placed in a horizontal posifion. The wheel can be controlled and maintained via a hinged door. We use different materials for classifier wheel to meet diferent.

We have developed several designs to meet different project requirements:

- HTS single-wheel

- HTS multi-wheel

- HTS-C for finer product

- HTS D for finer product & higher efficiency

Vertical Air Classifier – ITC

The lTC air classifier is designed for fine classifications in the range of 2 – 150 μm.This type of classifier belongs to the family of turbo classifiers. The wheel is placed in avertical position to get a good dispersion of the feed product.The feed is transported by the primary air stream into the classifying chamber or is fedfrom top by gravity. The secondary air stream enters the classifier from a ring of guidevanes or from air inlet at bottom cone.

The classifier can work independently or be integrated in a grinding – classifying circuit.

For this application a high feed rate with a good yield is assured.

The materials of construction are selected for highest strength during production.

We have developed several designs to meet different project requirements:

- ITC-S for coarse product

- ITC-C for finer product

- ITC-D for finer product & higher efficiency

Air Classifier – MBS

The MBS series air classifier is designed by German and British experts. It is used for efficient dry classification of D97: 8-200 micron powder. The classifier, cyclone collector, dust collector, and induced draft fan form a complete system. The classifier’s feeding port is at the top. The feed enters the classifier from the top inlet under gravity. The material falls onto the centrifugal dispersion disc of the classifying wheel. The material is evenly dispersed to the baffle ring. The material then falls into the grading area. Classification air enters the scroll housing. The air passes the guide vanes and moves inward to the classification wheel. Fine powder is carried by the airflow into the classifying wheel. The fine powder then enters the cyclone collector or dust collector. Coarse powder is repelled by the centrifugal force of the classifying wheel. The coarse powder falls into the lower body of the classifier.

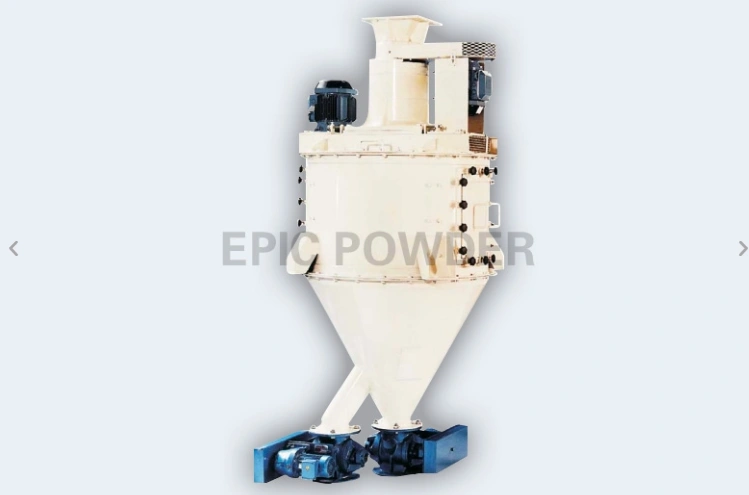

Air Classifier- CTC

Air Classifier CTC is an air-flow internal-recirculation centrifugal classifier, also called” Coarse Powder Classifier”, “Dedusting Classifier”, designed for high powder yield between 20micron and 200micron at low energy consumption. lts handling capacity can be 2 t/h – 80 t/h by its different models. We have 2 designs: with internal fan & without internal fan. lt does not require external powder filter collector & suction fan to complete the powder classification process. lt is used to produce fine powder product, and also is used for dedusting of sand product. Low-wear design is available for abrasive powder processing (Mohs hardness 6-8).

Epic powder

Epic Powder, 20+ years of work experience in the ultrafine powder industry. Actively promote the future development of ultra-fine powder, focusing on crushing,grinding,classifying and modification process of ultra-fine powder. Contact us for a free consultation and customized solutions! Our expert team is dedicated to providing high-quality products and services to maximize the value of your powder processing. Epic Powder—Your Trusted Powder Processing Expert !