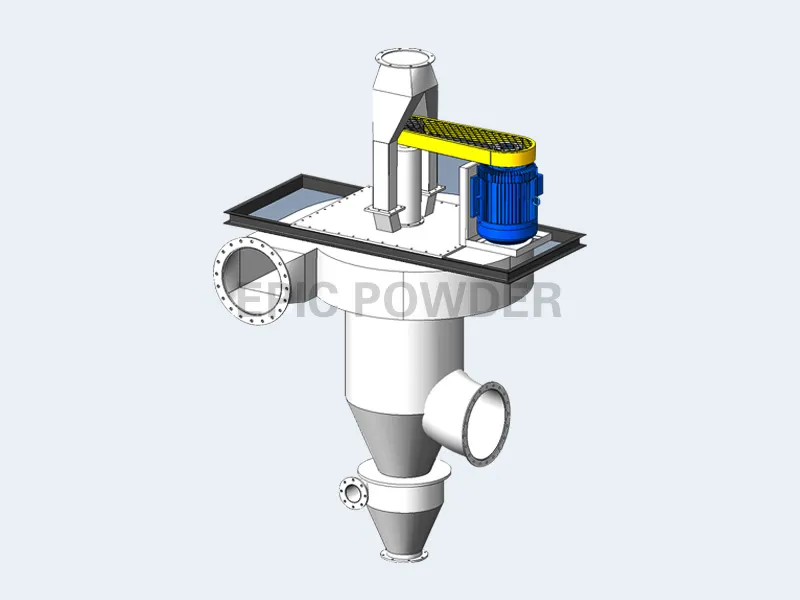

Air Classifier

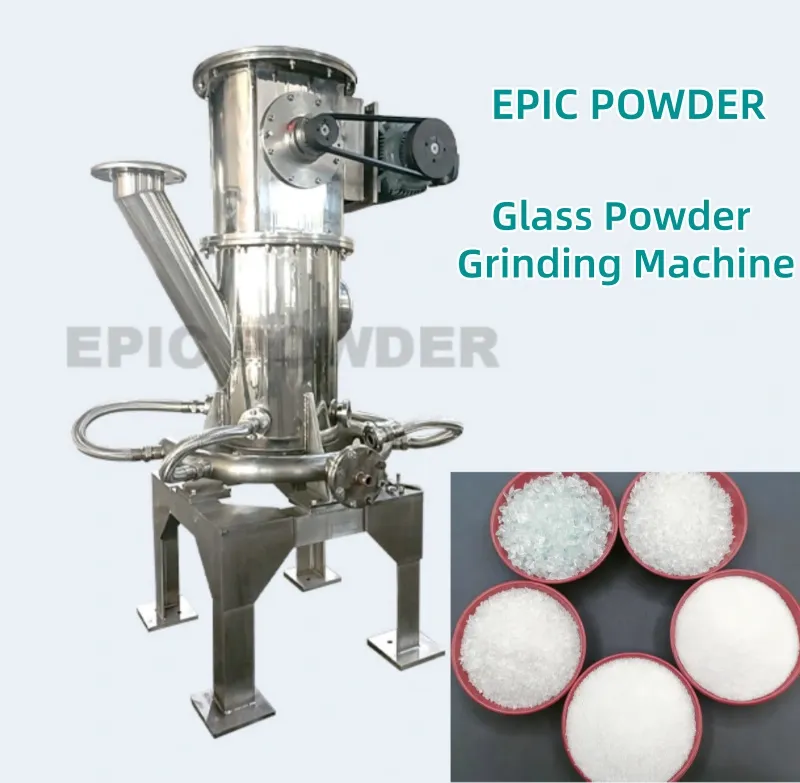

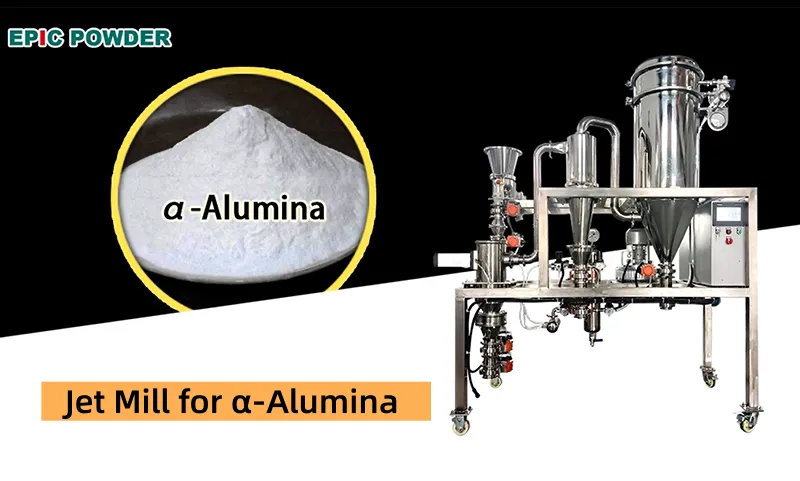

Air classifier is ideal for fine powders of ceramics, abrasives, glass, minerals, and polymers. If you’re unsure whether or not your particular feed will be a good fit, here are some material properties to consider.

Good candidates:

Dense materials

Hard materials

Round/spherical materials

Free-flowing materials

Materials that disperse well in air

Working Principle

Under the action of the fan, the material moves to the classification area at a high speed from the lower inlet of the classifier with the updraft. Under the action of the strong centrifugal force generated by the high-speed rotating classification turbine, the material is separated, and the fine particles meeting the particle size requirements enter the cyclone separator or dust collector through the blade gap of the classification wheel for collection. The velocity of some fine particles entrained by coarse particles disappears after hitting the wall, and then decreases to the secondary air outlet along the wall of the cylinder. Through the strong washing effect of the secondary air, the coarse and fine particles are separated, the fine particles rise to the secondary classification in the classification area, and the coarse particles drop to the discharge port for discharge.

Features And Benefits

Air Classifier is the process in which fine particles are separated by utilizing the opposing forces of centrifugal force and aerodynamic drag. An air classifier can precisely, predictably, and efficiently sort particles by mass, resulting in a coarse particle fraction and a fine particle fraction.

- A variety of classification rotor are available, and the output can be adjusted; speed of wheel is controlled by inverter, particle size can be adjusted freely. The classifying wheel can be made of ceramic materials, without metal pollution, meeting the requirements of high-purity materials.

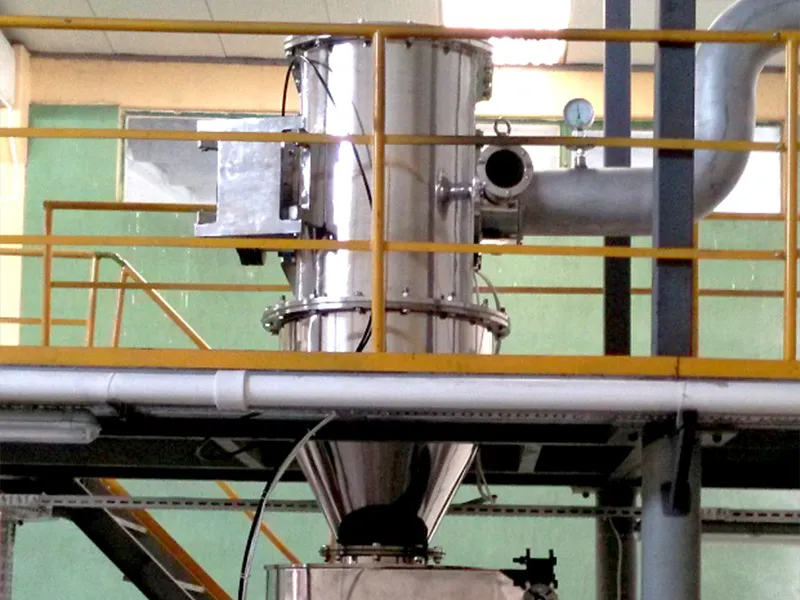

- Grinding is in closed system, little dust, low noise in a clean and environmentally friendly process.

- In conjunction with ball mill, table roller mill and Raymond mill to form closed circulation.

- Optional explosion-proof design, can also be upgraded to a nitrogen circulation system to meet the processing needs of flammable and explosive oxide materials.

Technical Parameters

Technical parameters of horizontal Multi rotor Air Classifier HTS

| MODEL | 200/4 | 315/3 | 315/4 | 315/6 | 400/6 | 500/3 | 500/4 | 500/6 | 630/6 |

|---|---|---|---|---|---|---|---|---|---|

| Particle size(D97:μm) | 3-120 | 3-150 | 3-150 | 3-150 | 4-150 | 5-150 | 5-150 | 5-150 | 6-150 |

| Classification efficiency(η) | 60~80% | 60~80% | 60~80% | 60~80% | 60~80% | 60~80% | 60~80% | 60~80% | 60~80% |

| Classifier motor(kw) | 5.5/7.5 x 4 | 15/18.5 x 3 | 15/18.5 x 4 | 15/18.5 x 6 | 18.5/22 x 6 | 22/30 x 3 | 22/30 x 4 | 22/30 x 6 | 30/45 x 6 |

| Air volume(m³/h) | 4800 | 10500 | 14000 | 21000 | 33600 | 26400 | 35200 | 52800 | 84000 |

Technical parameters of horizontal single rotor Air Classifier HTS

| MODEL | 70 | 315/3 | 315/4 | 315/6 | 400/6 | 500/3 | 500/4 | 500/6 | 630/6 |

|---|---|---|---|---|---|---|---|---|---|

| Particle size(D97:μm) | 3-120 | 3-150 | 3-150 | 3-150 | 4-150 | 5-150 | 5-150 | 5-150 | 6-150 |

| Classification efficiency(η) | 60~80% | 60~80% | 60~80% | 60~80% | 60~80% | 60~80% | 60~80% | 60~80% | 60~80% |

| Classifier motor(kw) | 5.5/7.5 x 4 | 15/18.5 x 3 | 15/18.5 x 4 | 15/18.5 x 6 | 18.5/22 x 6 | 22/30 x 3 | 22/30 x 4 | 22/30 x 6 | 30/45 x 6 |

| Air volume(m³/h) | 4800 | 10500 | 14000 | 21000 | 33600 | 26400 | 35200 | 52800 | 84000 |

Technical parameters of vertical single-rotor Air Classifier ITC

| MODEL | ITC-S2 | ITC-SI | ITC-1 | ITC-2 | ITC-3 | ITC-4 | ITC-5 | ITC-6 | ITC-7 | ITC-8 | ITC-9 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Particle size(D97:μm) | 5-100 | 6-150 | 6-150 | 8-150 | 8-150 | 10-150 | 15-150 | 20-150 | 25-150 | 25-150 | 30-150 |

| Classification efficiency(η) | 60-90% | 60-90% | 60-90% | 60-90% | 60-90% | 60-90% | 60-90% | 60-90% | 60-93% | 60-90% | 60-90% |

| Classifier motor(kw) | 4 | 7.5 | 11 | 15 | 22 | 37 | 37-45 | 45 | 55 | 75 | 110 |

| Air volume(m³/h) | 1200 | 2700 | 3900 | 6000 | 11000 | 17000 | 30000 | 43000 | 77000 | 120000 | 150000 |