Fluidized Bed Opposed Air Jet Mill

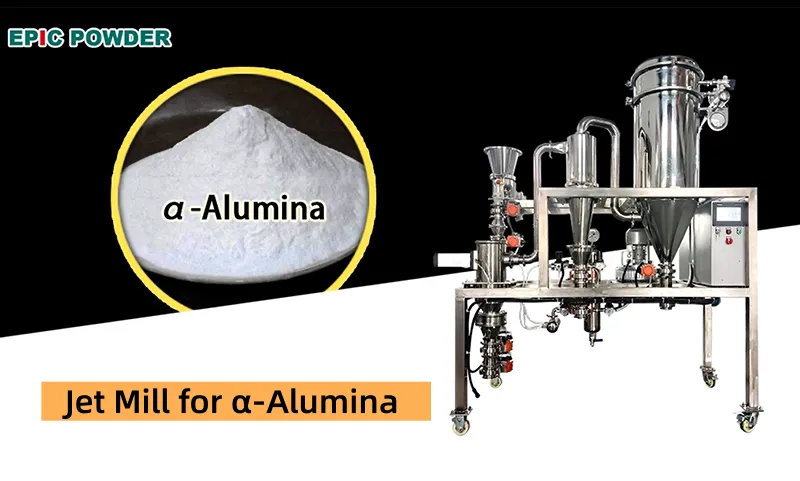

Suitable for grinding materials with high hardness, high purity and high added value.

Fluidized Bed Opposed Air Jet Mill incorporates dense phase micronization using turbulent, free jets in combination with high efficiency centrifugal air classification within a common housing. This combination allows for enhanced comminution by high probability particle-on-particle impact for breakage and a high degree of particle dispersion for improved separation.

Working Principle

Fluidized Bed Opposed Air Jet Mill: After the compressed air is filtered and dried, it is sprayed into the grinding chamber at high speed through the Laval nozzle. At the intersection of multiple high-pressure airflows, the materials are repeatedly collided, rubbed, and sheared to be crushed. The crushed materials rise with the suction of the fan. The airflow moves to the classification zone. Under the action of the strong centrifugal force generated by the high-speed rotating classification turbine, the coarse and fine materials are separated. The fine particles that meet the particle size requirements enter the cyclone separator and dust collector through the classification wheel for collection, and the coarse particles descend to the crushing zone and continue to be crushed.

Features And Benefits

Fluidized Bed Opposed Air Jet Mill incorporates dense phase micronization using turbulent, free jets in combination with high efficiency centrifugal air classification within a common housing. This combination allows for enhanced comminution by high probability particle-on-particle impact for breakage and a high degree of particle dispersion for improved separation.

- Low-temperature pulverization without medium, especially suitable for heat-sensitive, low-melting materials.

- Control particle sizes precisely, available particle size D50:1~25μm.

- Grinding in a complete closed system, no dust, low noise, clean and environmentally friendly.

- Jet Milling is an effficient way to mill or micronize various chemicals, polymers, ceramics and other friable materials. Abrasive and temperature-sensitive products can be finely ground with minimum contamination. The simple, easy-to-clean, cost-effective design offers precise top size control with narrow size distributions in the 95% < 5 um to 95% < 70 um size range. Load cells are used to precisely control mill load for optimum grinding efficiency and/or product size distribution control.

Technical Parameters

Technical parameters of horizontal fluidized bed opposed air jet mill / Jet milling machine MQW

| MODEL | MQW03 | MQW06 | MQW10 | MQW20 | MQW30 | MQW40 | MQW60 | MQW80 | MQW120 | MQW160 | MQW240 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Feeding Size(mm) | <1 | <2 | <2 | <3 | <3 | <3 | <3 | <3 | <3 | <3 | <3 |

| Production Capacity(kg/h) | 0.3~10 | 10~150 | 20~300 | 40~600 | 100~900 | 200~1200 | 500~2000 | 800~3000 | 1500~6000 | 2000~8000 | 4000~12000 |

| Particle size(D97:μm) | 3~45 | 3~45 | 3~45 | 3~45 | 3~45 | 3~45 | 3~45 | 3~45 | 3~45 | 3~45 | 3~45 |

| Classifier motor (kw) | 2.2 | 3 | 5.5/7.5 | 7.5/11 | 11/15 | 15/7.5x3 | 7.5x3 | 11x3 | 15x3 | 15x4 | 15x6 |

| Air consumption(m³/min) | 3 | 6 | 10 | 20 | 30 | 40 | 60 | 80 | 120 | 160 | 240 |

| Air pressure(Mpa) | 0.6~1 | 0.6~1 | 0.6~1 | 0.6~1 | 0.6~1 | 0.6~1 | 0.6~1 | 0.6~1 | 0.6~1 | 0.6~1 | 0.6~1 |

Technical parameters of vertical fluidized bed opposed air jet mill MQL

| MODEL | MQL03 | MQL06 | MQL10 | MQL20 | MQW30 | MQW40 | MQW60 | MQW80 | MQW120 | MQW160 | MQW240 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Feeding Size(mm) | <1 | <2 | <2 | <3 | <3 | <3 | <3 | <3 | <3 | <3 | <3 |

| Production Capacity(kg/h) | 1~10 | 10~150 | 20~300 | 40~600 | 100~900 | 200~1200 | 500~2000 | 800~3000 | 1500~6000 | 2000~8000 | 4000~12000 |

| Particle size(D97:μm) | 6~150 | 6~150 | 6~150 | 6~150 | 6~150 | 8~150 | 8~150 | 8~150 | 8~150 | 8~150 | 8~150 |

| Classifier motor (kw) | 4 | 4 | 5.5 | 7.5 | 7.5 | 11 | 18.5 | 18.5 | 30 | 45 | 55 |

| Air consumption(m³/min) | 3 | 6 | 10 | 20 | 30 | 40 | 60 | 80 | 120 | 160 | 240 |

| Air pressure(Mpa) | 0.6~1 | 0.6~1 | 0.6~1 | 0.6~1 | 0.6~1 | 0.6~1 | 0.6~1 | 0.6~1 | 0.6~1 | 0.6~1 | 0.6~1 |