With the increasing prevalence of cardiovascular diseases, antithrombotic pharmaceutical—as core therapeutics for preventing and treating thromboembolic disorders—are witnessing growing market demand. However, traditional formulation processes face bottlenecks in maintaining pharmaceutical stability, dissolution rates, and bioavailability. Recent breakthroughs in jet mill technology have emerged as innovative solutions, positioning its application in antithrombotic pharmaceutical micronization as an industry focal point

Jet Mill Technology: From Principles to Pharmaceutical Advantages

- Low-Temperature Environment: Limited heat generation due to energy conversion, maintaining temperatures below room temperature to protect heat-sensitive components .

- High-Purity Processing: Closed systems minimize cross-contamination, while inert gas protection (e.g., nitrogen) prevents oxidation of reactive pharmaceutical.

- Precise Particle Control: Achieves D50 particle sizes of 1–50 μm, meeting diverse formulation needs (e.g., fast-dissolving tablets require <10 μm, extended-release formulations up to 50 μm)

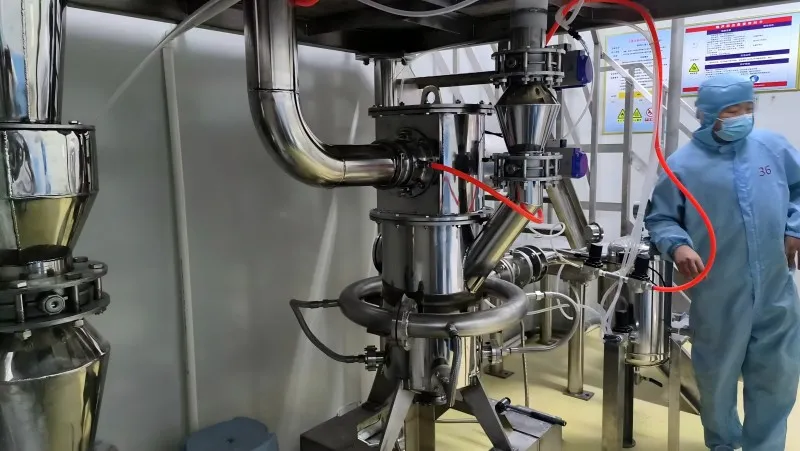

Mechanism and Advantages of Jet Mill

Jet mill employs high-velocity airflow collisions to reduce pharmaceutical particles to micro- or nano-scales (1–10 μm). Key advantages include:

- Enhanced Solubility: Increased surface area-to-volume ratio accelerates dissolution, critical for poorly water-soluble drugs like .

- Thermal Stability: Unlike traditional grinding, jet mill avoids heat generation, preserving the integrity of thermolabile compounds.

- Scalability: Continuous processing and compliance with Good Manufacturing Practice (GMP) make it suitable for large-scale production.

- Traditional mechanical grinding struggles with thermal degradation and mechanical stress, whereas jet milling’s gentle dispersion mechanism offers an optimal solution.

Industrial and Clinical Advancements

Commercial Success

- Hirudin Formulations: Jet-milled hirudin (from leeches) demonstrated superior absorption in anticoagulant therapies, with a 40% reduction in clotting time in clinical trials.

Future Perspectives

Multifunctional Platforms

- Theranostic Systems: Iron oxide-integrated jet-milled particles enable simultaneous thrombolysis and MRI-guided monitoring.

- 3D-Printed Dosages: Hybrid jet milling and 3D printing technologies allow patient-specific pharmaceutical release profiles.

Global Health Impact

- Cost-effective production methods could democratize access to advanced antithrombotic therapies in low-resource regions

Conclusion

Jet mill technology is revolutionizing antithrombotic pharmaceutical development by enhancing efficacy, reducing costs, and enabling sustainable production. From mitigating thermal degradation to enabling smart delivery systems, this “micron-scale revolution” exemplifies the convergence of interdisciplinary innovation. As AI-driven process optimization and hybrid technologies (e.g., 3D printing) mature, jet mill will propel the pharmaceutical industry into an era of precision, efficiency, and sustainability.