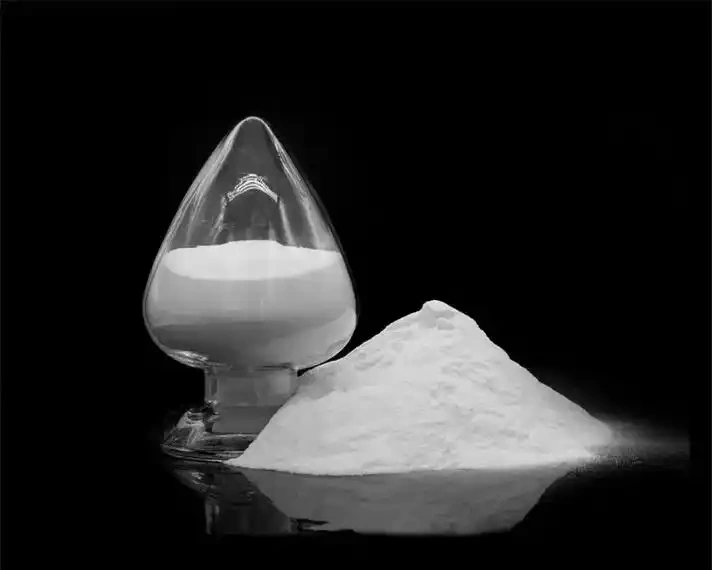

White carbon black (also known as precipitated silica) is an inorganic non-metallic material with high specific surface area and excellent dispersibility. With its lightweight, reinforcing, heat-resistant, and multifunctional properties, it is widely applied in rubber, plastics, coatings, chemicals, and new energy industries. As downstream industries evolve, the preparation technologies and performance of white carbon black continue to improve, forming multiple technical routes and differentiated applications.

Technical Routes

Fumed Silica (Gas-Phase Method)

- Principle: Hydrolysis of silicon compounds (such as silicon tetrachloride) at high temperature to form nanoscale silica.

- Features: Extremely high purity (>99.8%), very small particle size (5–50nm), but higher production cost.

- Applications: Mainly used in high-end silicone rubber as a reinforcing agent, enhancing strength and weather resistance through physical adsorption and chemical bonds (e.g., Si–O–Si).

Precipitation Method

- Principle: Produced from sodium silicate and sulfuric acid through acidification, precipitation, washing, and drying.

- Features: Broader particle size range (5–150nm), specific surface area of 100–400 m²/g, and porous structure.

- Applications: Accounts for more than 70% of industrial white carbon black, widely used in rubber, coatings, and plastics.

Core Property Comparison

| Property | Fumed Silica | Precipitated Silica |

| Purity | 99.8% | ~90% |

| Particle size | 5–50nm | 11–150nm |

| Specific area | Higher (not specified) | 100–400 m²/g |

| Cost | High | Low |

| Processability | Difficult to disperse | Easy to process |

Key Processes of Precipitation Method

Acidification reaction: Sodium silicate reacts with sulfuric acid to generate silica sol.

Precipitation control: Adjusting pH and temperature to form desired pore structure.

Washing and drying: Removing impurities, spray drying to retain porous characteristics.

Emerging Technical Routes

Special Precipitation Methods: Technologies such as supergravity method, reverse micelle microemulsion, and secondary crystallization can improve dispersibility and specific surface area.

Resource-based Preparation: For example, Hubei Yihua uses fluorosilicon raw materials with dispersants and ammonia (pH precisely controlled at 9.3–9.4), simultaneously producing high-surface-area silica (>300 m²/g) and ammonium fluoride.

Combustion Loss Method: Purification via petroleum catalyst combustion loss, optimizing silica performance for rubber toughening.

Application Scenarios and Performance Contributions

Rubber Industry

- Tire tread: Tensile strength ↑30–50%, wear resistance ↑2x, rolling resistance ↓10–15%.

- Colored rubber products: Replace carbon black to achieve transparency and aesthetic design.

New Energy and Advanced Materials

- Lithium battery separators: After coating, thermal stability reaches 180°C without shrinkage.

- 3D printing resins: Used as light diffusers to control transmittance (10–90%).

Other Fields

- Coatings: Adding 2–3% improves leveling and increases anti-sagging performance by 50%.

- Cosmetics: Enhances SPF value of sunscreens by ~25%.

- Agrochemicals: Suspension rate improved from 65% to 90%.

Development Trends

Surface Modification: Surface treatment (e.g., silane coupling agents) to improve polymer compatibility and reinforcement.

Green & Low-Carbon Processes: Resource utilization technologies to reduce energy consumption and emissions.

Functional Applications: Expanding into new energy, electronic materials, and 3D printing.

Epic Powder

White carbon black, known as the “MSG of industry,” continues to evolve in both performance and applications. From traditional rubber reinforcement to lithium battery separators, optical materials, and functional coatings, its role is expanding across multiple industries. With the advancement of preparation and surface modification technologies, white carbon black will unlock greater potential in high-performance and high-value-added applications.

Epic Powder, with over 20 years of expertise in powder processing, leverages advanced jet mills, ball mills, classifiers, and surface modification equipment to deliver customized grinding and classification solutions. By precisely controlling particle size distribution, specific surface area, and dispersibility, Epic Powder empowers white carbon black to achieve superior performance in new energy and advanced material applications.