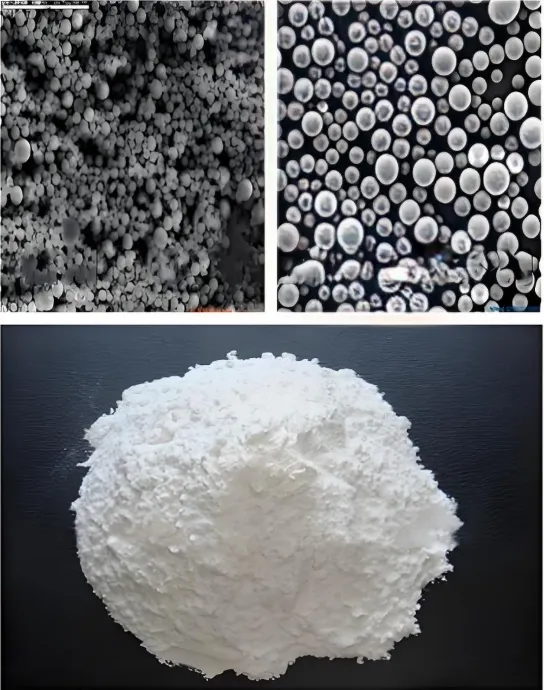

Silica powder is a very important inorganic non-metallic functional filler. It can be compounded with organic polymers and improve the overall performance of composite materials. It is widely used in electrical and electronic, silicone rubber, coatings, adhesives, potting materials and other fields.

Silica powder itself is a polar and hydrophilic substance. Different from the interface properties of the polymer matrix, it has poor compatibility. It is often difficult to disperse in the base material. Therefore, in order to make the composite material have better performance, it is usually necessary to modify the surface of silica powder. The physical and chemical properties of the surface of silica powder are purposefully changed according to the needs of the application. Thereby improving its compatibility with organic polymer materials and meeting its dispersibility and fluidity requirements in polymer materials.

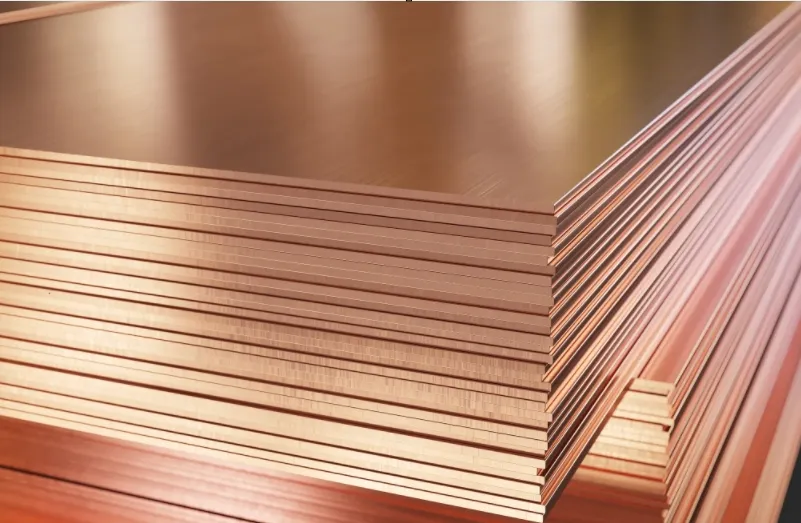

Copper Clad Laminate

Copper clad laminate is a key electronic material. It is made by soaking glass fiber or other reinforcements in resin, adding fillers, and covering with copper foil. The process includes glue mixing, impregnation, and hot pressing. Adding modified silicon powder lowers production cost. It also improves heat resistance, conductivity, and mechanical strength.

rubber

Rubber is a highly elastic polymer material with reversible deformation. It can be widely used in many fields such as electronics, automobiles, civil engineering, medical care, and daily necessities. During the rubber preparation process, a certain amount of inorganic filler is added. This can not only reduce the production cost of rubber, but also significantly improve the comprehensive physical properties and dynamic mechanical properties of rubber composite materials.

plastic

Silica powder can be used as filler in materials such as polyethylene (PE), polyvinyl chloride (PVC), polypropylene (PP), polyphenylene ether (PPO) in the process of making plastics. It is widely used in many fields such as construction, automobiles, electronic communication insulation materials, agriculture, daily necessities, etc.

Epoxy molding compound

Epoxy molding compound is a molding compound mixed with a variety of additives. It is a key material for electronic packaging and accounts for more than 97% of the market for microelectronic packaging. It can be widely used in various packaging fields such as semiconductors, consumer electronics, integrated circuits, and aviation.

Epoxy castings

Epoxy insulation casting material is a liquid or viscous polymerizable resin mixture made of resin, curing agent, filler, etc. At the casting temperature, the casting material has good fluidity and less volatiles, fast curing, and small shrinkage after curing. The epoxy resin formed after the casting material is cured. Epoxy resin is an insulating product that integrates multiple functions such as insulation, moisture-proof, mildew-proof, anti-corrosion, fixation and isolation.

Electronic potting glue

Potting glue is often used in electronic components, mainly for bonding, sealing, blocking and protection. Before curing, it is in liquid state and has a certain fluidity. The viscosity of the glue varies according to the material, performance and production process of the product. And only after the glue is completely cured can its use value be realized.

Artificial quartz

Silicon powder is used as a filler in artificial quartz. It can not only reduce the consumption of unsaturated resin, but also improve the wear resistance, acid and alkali resistance, mechanical strength and other properties of artificial quartz plates.

conclusion

In addition, modified silicon micropowder is also widely used in advanced ceramics, welding rod protective layer. And APG process injection materials, adhesives, anti-adhesion agents, anti-caking agents, inks and other fields. The addition of modified silicon micropowder not only greatly reduces the cost, but also improves the processing performance of the mixed material.

Different application fields of silicon micropowder have different quality requirements. Therefore, when choosing the application of silicon micropowder, it should be combined with the needs of downstream industries. Consider comprehensive factors such as cost, efficiency, performance, etc., and choose the appropriate type of silicon micropowder, modifier and formula.

Epic powder

Epic Powder, 20+ years of work experience in the ultrafine powder industry. Actively promote the future development of ultra-fine powder, focusing on crushing, grinding, classifying and modification process of ultra-fine powder. Contact us for a free consultation and customized solutions! Our expert team is dedicated to providing high-quality products and services to maximize the value of your powder processing. Epic Powder—Your Trusted Powder Processing Expert !