Perlite, a volcanic glass rock predominantly composed of SiO₂ (70-75%), undergoes high-temperature expansion to form a lightweight porous structure. To achieve precise particle size distribution (1-100 μm) for industrial applications, specialized perlite powder grinding machines are employed in the comminution process. These grinders utilize mechanical shear forces or jet milling technology to control the final powder’s specific surface area and bulk density, which directly influence its thermal insulation and adsorption performance.

- Lightweight and Low Density: Bulk density of 0.1-0.3 g/cm³, very light, suitable for applications requiring low weight.

- High Surface Area: 1-5 m²/g, with excellent adsorption properties, able to effectively absorb moisture and pollutants.

- High-Temperature Resistance: Melting point around 1300°C, making it ideal for refractory materials.

- Chemical Stability: Acid and alkali resistant, non-toxic, and harmless.

- Low Thermal Conductivity: 0.04-0.06 W/(m·K), offering excellent insulation and thermal conductivity performance.

These unique physical and chemical properties make perlite powder an ideal choice for a variety of applications.

Preparation Process of Perlite Powder

The preparation of perlite powder includes several stages, from raw material pre-treatment to fine grinding and surface modification. Below is a detailed process description:

Raw Material Pre-treatment

Perlite ore needs to be crushed to 2-5 mm before expansion. Impurities are removed to ensure uniform expansion in the following steps.

High-Temperature Expansion

Perlite ore is heated instantaneously at temperatures of 900-1200°C, causing the combined water inside the ore to vaporize, resulting in an expansion of 10-30 times. Common expansion equipment includes:

- Vertical Expanding Furnace: Low energy consumption, suitable for small-scale production.

- Rotary Kiln: Ensures uniform expansion, suitable for industrial continuous production.

Ultra-Fine perlite powder grinding machines

The expanded perlite particles need to be further crushed to a micron size. The main grinding methods include:

- Ring Roller Mill: Material is crushed through compression and shear between the grinding ring and rollers. It consumes less energy, suitable for materials of medium hardness, and can produce powder with a D97 ≤ 10 μm. It is suitable for large-scale production.

- Ball Mill: Steel or ceramic balls are used for impact and grinding. Simple and cost-effective, it can grind wet or dry. However, its grinding efficiency is lower, and it is better suited for coarse grinding (D50 ≥ 20 μm).

- Air Classifier Mill: High-speed airflow is used to make particles collide and grind. This method is pollution-free, yielding high-purity products with submicron particle sizes (D50 ≤ 5 μm). It is suitable for high-value-added products, but energy consumption is relatively high.

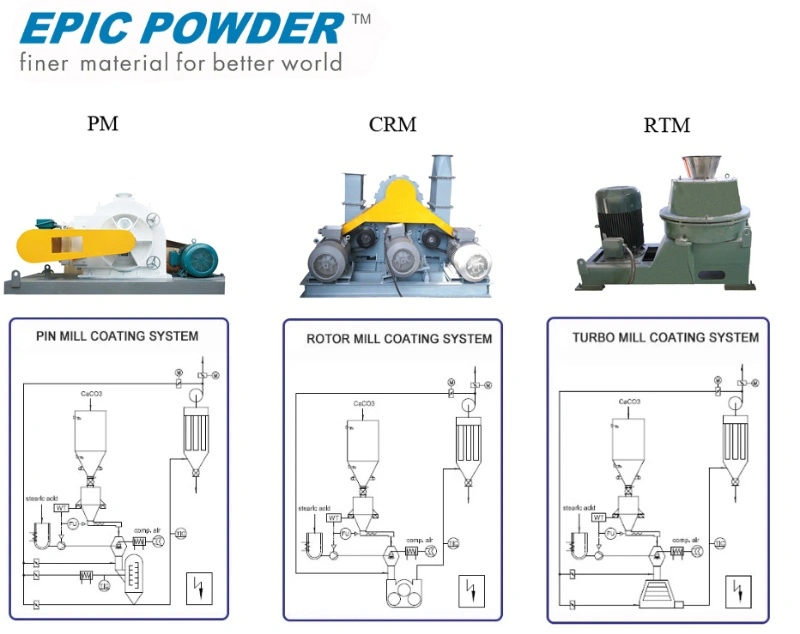

Surface Modification

Surface modification with silane coupling agents, stearic acid, etc., improves the dispersion and compatibility of perlite powder in polymer, coating, and other systems. This step significantly enhances the performance of perlite powder, making it more versatile for various applications.

Applications of Perlite Powder

Building Materials:

- Lightweight Insulating Mortar: Perlite powder reduces the density of mortar and improves thermal insulation performance, commonly used in exterior wall insulation and building insulation layers.

- Fireproof Coatings: Perlite powder, with its high-temperature resistance, is used in fireproof coatings to delay fire spread, enhancing building fire safety.

- Soundproof Materials: The porous structure of perlite powder effectively absorbs sound waves, making it suitable for soundproof materials, especially in building decoration and audio equipment.

Chemical and Environmental Protection:

- Catalyst Carrier: The high surface area of perlite powder makes it an ideal catalyst carrier, improving the loading efficiency of active components, widely used in petroleum and chemical industries.

- Wastewater Treatment: Perlite powder can adsorb heavy metals (such as Pb²⁺, Cd²⁺) and organic pollutants, making it an effective material for wastewater treatment.

- Oil Spill Absorbent: Perlite powder is used for cleaning up oil spills in marine or industrial environments, thanks to its high adsorption capacity, which quickly removes oil contaminants.

Agriculture and Horticulture:

- Soil Amendment: Perlite powder is used to improve soil aeration and water retention, promoting healthy plant growth. It is particularly effective in greenhouse cultivation and potted plants.

- Slow-Release Fertilizer Carrier: Perlite powder acts as a carrier for slow-release fertilizers, improving fertilizer efficiency and reducing waste.

Fireworks Industry:

- Flame Color Enhancer: Perlite powder serves as an inert carrier for evenly dispersing metal salts (such as Sr, Cu), enhancing flame color effects in fireworks.

- Safe Burn Rate Modifier: It adjusts the burn rate, improving the stability of fireworks during combustion.

- Smoke Effect Regulator: Perlite’s porous structure helps control the release rate of smoke, enhancing the visual impact of fireworks.

Research Challenges and Prospects

As the demand for perlite powder continues to grow, there are several challenges in its production process:

- Process Optimization: There is a need for developing low-energy consumption expansion and grinding technologies, such as plasma-assisted expansion, to reduce production costs.

- Functional Modification: By using nano-composites or chemical modifications, the adsorption and catalytic performance of perlite powder can be enhanced to meet the needs of specialized materials.

- Emerging Applications: There is great potential for exploring new uses of perlite powder in fields such as lithium battery separators, 3D printing materials, and special fireworks effects.

epic powder

Perlite powder, with its unique porous structure and SiO₂-rich composition (70-75%), demonstrates vast potential across green building, new energy, and environmental protection sectors. To maximize its performance in these applications, perlite powder grinding machines play a pivotal role in achieving precise particle size distribution (1-100 μm) and optimized surface morphology. As an industry leader, Epic Powder integrates advanced grinding technologies—including jet milling and classifier-integrated systems—into its equipment lineup, ensuring energy-efficient production of high-quality perlite powders. Through continuous innovation in grinding process optimization and surface modification techniques, Epic Powder’s solutions not only enhance material sustainability but also enable cost-effective scaling for specialty applications like phase-change materials and filtration media.