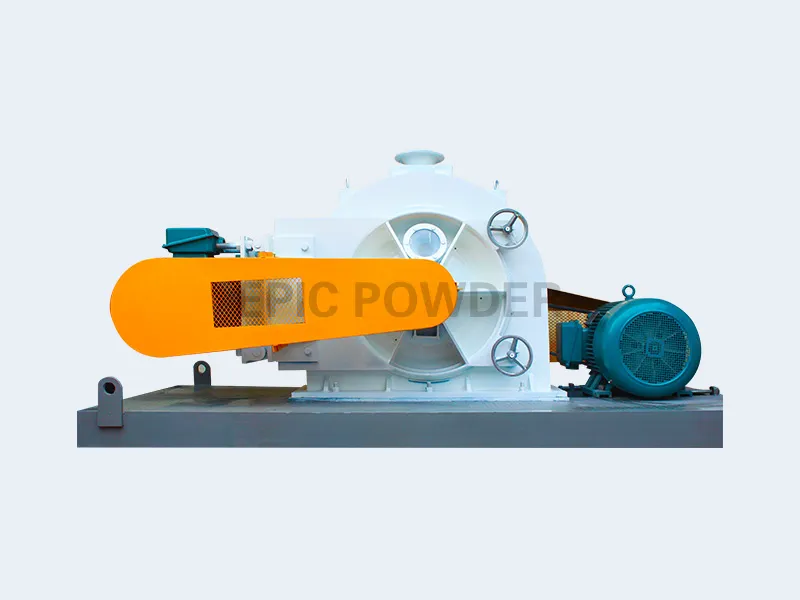

Three-Roller Coating Machine

This continuous powder surface coating system is designed on the base of German know how with Chinese equipment, and can be used for coating of various powders like calcium carbonate (GCC, PCC), kaolin, talc, mica, graphite, barium sulfate, white carbon black, magnesium hydrate, zinc oxide, aluminum oxide, and is suitable for a variety of solid/liquid coating agents, like aluminate coupling agent, titanate coupling agent, silane coupling agent and stearic acid.

Working Principle

This continuous powder surface coating system is designed on the base of German know how with Chinese equipment, and can be used for coating of various powders like calcium carbonate (GCC, PCC), kaolin, talc, mica, graphite, barium sulfate, white carbon black, magnesium hydrate, zinc oxide, aluminum oxide, and is suitable for a variety of solid/liquid coating agents, like aluminate coupling agent, titanate coupling agent, silane coupling agent and stearic acid.

Coating machine consists of three units of mixing rooms. High-speed rotation creates great vortex flow inside these special-shaped rooms. Powder and coating agent are mixed in the high-speed gas-solid vortex flows. Coating machine with both surface coating and particle dispersing functions is suitable for various powders with different fineness, and has a unique coating effect for the materials with small apparent specific gravity and high volume to weight ratio.

Automatic temperature control system ensures stable high temperature for coating agent melting into liquid and mixing with uncoated powder. Heating and cooling of powder and coating agent are completed in one machine, which does not need independent cooling system.

High utilization ratio of coating agent, high powder-coated rate, high activation grade, low energy consumption, and very few agglomerates in final coated product. The whole system is operated under negative pressure, no dust emission, and low labor intensity.

Features And Benefits

- Realize powder surface modification by changing inner vortex with three rotating rotors.

- Mature technology, low investment, suitable for stearic acid coating.

- Self-friction generates heat, no heating device is needed, less auxiliary machine, and low operating cost.

- Suitable for powder coatings of 325~3000 mesh.

- Power range: 11kW~225kW; Maximum output: 6t/h.

- The air volume is small, the dispersibility is poor, especially the fine powder, and the amount of modifier is large.

- Self-friction heat generation is easily affected by environmental factors, and the modification temperature is poorly controllable.

- There is a dead zone and the coating rate is low.

Related Products

Technical Parameters

| Model | CRM-3 | CRM-6 | CRM-9 |

|---|---|---|---|

| Standard drive (kW) | 18.5 x 3 | 37 x 3 | 75 x 3 |

| Fineness (μm) | 3 – 75 | 3 – 75 | 3 – 75 |

| Capacity (t/h) | 0.5 – 2 | 1 – 6 | 2 – 12 |