To purify quartz ore, the raw material must first undergo crushing and classification preprocessing. The goal is to achieve the preliminary separation of quartz from associated minerals and provide raw materials within an appropriate particle size range for subsequent processing and purification. This preprocessing step helps improve the purity and efficiency of the quartz purification process.

Quartz crushing

The purpose of crushing is to reduce the quartz ore to the required particle size. This helps release impurities for subsequent treatment. Methods include mechanical crushing, electric crushing, ultrasonic crushing, and thermal shock crushing. During the crushing process, two factors must be considered: the dissociation effect of effective monomers and secondary pollution.

The traditional mechanical method uses a jaw crusher or cone crusher to crush the mineral. This results in an irregular and angular particle shape. The jaw crusher is suitable for coarse crushing, the cone crusher for medium and fine crushing, and the impact crusher for fine crushing and coarse grinding.

To avoid secondary pollution from iron impurities and improve dissociation, methods like thermal crushing, high-pressure pulse crushing, and ultrasonic crushing can be used. However, these methods have high energy consumption and cost.

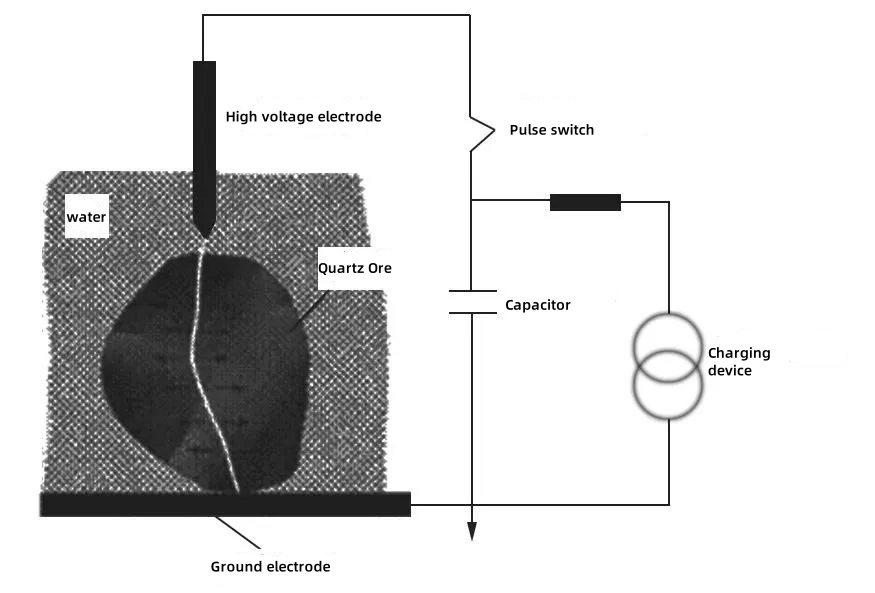

Pulse discharge fragmentation

Compared with traditional mechanical methods, pulse discharge rock crushing has more obvious advantages. It is mainly divided into two forms: hydroelectric effect crushing and electric crushing. The shock wave generated by high-voltage discharge causes the rock to break along the grain boundary. It selectively targets the mineral inclusions, aiding in the release of impurities and subsequent processing. This method also helps retain the particle size and morphology of the minerals to the greatest extent. Pulse discharge crushing is usually carried out in a water medium, making it dust-free and environmentally friendly.

Compared to traditional crushing, electric crushing is more effective in handling impurities. It does not introduce a large amount of iron pollution. The impurity content of K, Ti, and Fe after electric crushing is lower than that of mechanical treatment.

Ultrasonication

Ultrasonic fragmentation is based on the mechanical energy of ultrasound. When the ultrasonic pulverizer acts on the liquid, the liquid molecules generate a large number of small bubbles due to cavitation. The huge pressure generated by the bursting of the bubbles peels off the impurities on the surface of the particles.

Thermal crushing

Thermal crushing involves heating quartz ore to a specific temperature, causing it to expand in volume or undergo a phase change. This generates numerous tiny cracks, significantly reducing its mechanical strength, after which the quartz ore is crushed.

Quartz grinding

Grinding and classification follow the crushing process. Since grinding involves reducing ore from coarse to fine, it is essential to use the right methods. This ensures timely separation of products with qualified particle sizes for classification. It also helps avoid over-grinding and improves efficiency and production.

The complete production line of a ball mill and classifier is ideal for ultra-fine grinding of quartz. It offers high product whiteness, good shape, and gloss. The quality indicators are stable, and the particle size distribution is highly controllable.

Key points of ball milling technology

Due to the high hardness of quartz, it causes serious wear on the equipment and can contaminate the product. To prevent re-contamination, the equipment must be treated with wear-resistant protection, especially for electronic-grade high-purity silicon micropowder. All cavities, pipelines, and stationary parts should be lined with ceramic or organic wear-resistant materials. Ball mills typically use alumina liners or ball stone liners and employ zirconium balls or agate as grinding media. This reduces the impact of impurities such as iron or aluminum.

Quartz is hard and wear-resistant. When fine grinding is required, it is difficult to achieve the desired fineness using just the grinding medium. Therefore, grinding aids are often added to improve the grinding effect. Adding grinding aids or combined aids reduces the slurry’s viscosity, making it more fluid. This increases the yield of qualified particle size products.

Common grinding aids include triethanolamine, DA dispersant, stearic acid, ammonium chloride, sodium chloride, alcohol, sodium oleate, sodium silicate, and dodecylamine. Fatty alcohol polyoxyethyl ether and dodecyl trimethyl ammonium chloride are also used for testing.

Different industries and quartz products have strict regulations on particle size distribution. For example, manufacturing quartz crucibles for the semiconductor industry requires the quartz sand particle size to be between 0.180 and 0.125 mm. Therefore, the particle size of quartz must be carefully controlled during grinding to avoid over-grinding.

epic powder

Epic Powder, 20+ years of work experience in the ultrafine powder industry. Actively promote the future development of ultra-fine powder, focusing on crushing, grinding, classifying and modification process of ultra-fine powder. Contact us for a free consultation and customized solutions! Our expert team is dedicated to providing high-quality products and services to maximize the value of your powder processing. Epic Powder—Your Trusted Powder Processing Expert !