Lithium batteries are primarily composed of four key materials: cathode material, anode material, separator, and electrolyte. The anode material plays a crucial role in storing and releasing energy in lithium batteries, significantly affecting their first-cycle efficiency, cycle performance, and more. The anode material accounts for 6% to 10% of the total cost of a lithium battery. Currently, the majority of anode materials in the market are artificial graphite and natural graphite. We will introduce the production process of artificial graphite.

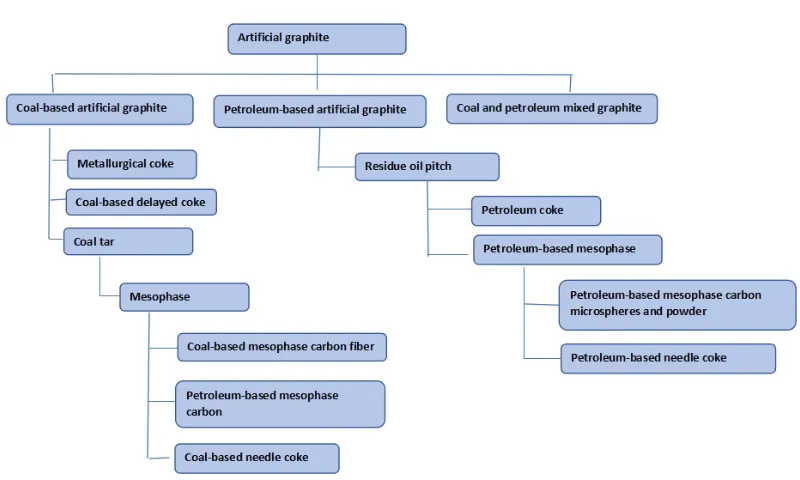

Artificial graphite anode undergoes four major processes and more than ten sub-processes. The raw materials for artificial graphite are divided into three categories: coal-based, petroleum-based, and a mixture of coal and petroleum. Among these, coal-based needle coke, petroleum-based needle coke, and petroleum coke are the most commonly used. Generally, for anode materials with high specific capacity, needle coke is used as the raw material, while petroleum coke, which is cheaper, is used for anodes with lower specific capacity. Asphalt is used as the binder.

Artificial graphite Anode process

Crushing, Coating, and Kneading

The graphite raw materials (needle coke or petroleum coke) are mixed with a binder in a fixed ratio of 100: (5-20). The material is fed into a hopper via a vacuum feeding system and then transferred into an air jet mill for air jet mill. The raw materials, initially 5-10mm in size, are ground down to 5-10 microns. After air jet milling, the material is collected by a cyclone dust collector. The dust collection rate is approximately 80%. The exhaust gas is filtered through a filter cartridge and then released. The dust removal efficiency is greater than 99%. The filter cartridge material has pores smaller than 0.2 microns, ensuring that dust particles larger than 0.2 microns are completely captured. A fan controls the entire system to maintain a negative pressure state.

Primary Granulation

The uniformly mixed material undergoes granulation to form the semi-finished negative electrode. Granulation is the core step in artificial graphite production. The particle size directly impacts the electrode’s performance. Larger particles are prone to expansion and have a short cycle life, while smaller particles require more binder, which affects the battery’s energy density. Therefore, high-end artificial graphite is usually subjected to secondary granulation after graphitization, binding 7-8 smaller particles together. This ensures both expansion performance and energy density.

Pyrolysis Granulation:

The material is stirred at 200-300°C for 1-3 hours, then heated to 400-500°C. After stirring, the particle size of the material reaches 10-20 microns, and then it is cooled and discharged.

Ball Milling and Screening:

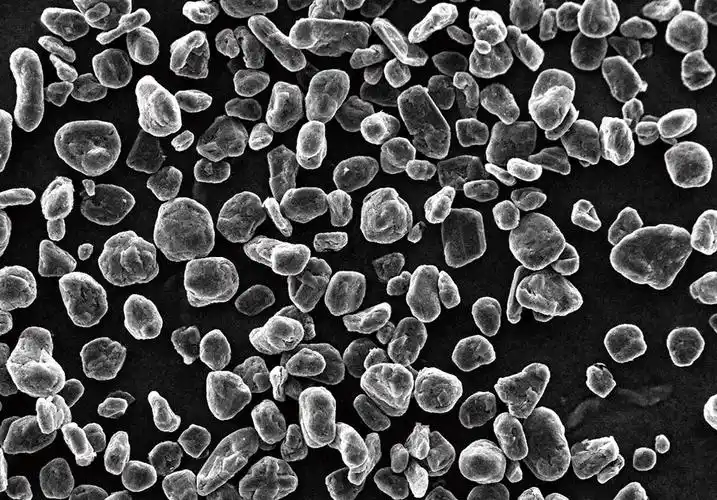

The material with a particle size of 10-20 microns is processed using a ball mill to reduce the size to 6-10 microns. It is then conveyed through pipes to a screening machine for separation.

Graphitization

The granulated material undergoes graphitization at a temperature of 2200-3300°C for at least 8 hours.

Graphitization refers to the process of transforming carbon atoms from a disordered structure into an ordered hexagonal plane lattice structure. The goal is to achieve properties such as high electrical conductivity, high thermal conductivity, corrosion resistance, and wear resistance. During heating, the microcrystals in the coke grow as the temperature increases. The distortions and defects in the microcrystals are gradually eliminated, leading to a transformation into graphitized carbon. The higher the graphitization temperature, the more complete the development of the microcrystal structure (and the higher the graphitization degree).

Secondary Granulation

Secondary granulation is done after crushing the raw material into small particles. Asphalt is used as a binder. The granulation occurs in a reactor. The target particle size is achieved during this process. The secondary granulation enhances the Li+ lattice embedding and de-embedding channels. This improves the rate capability and low-temperature performance of the negative electrode.

Coating and Carbonization

In this step, asphalt and resin-based polymers are added to the secondary granulated material in specific proportions. The mixture is then carbonized at temperatures between 1000-1300°C. This results in an amorphous carbon layer coating on the surface of the artificial graphite. This coating optimizes the lithium ion transfer rate during charging and discharging, enhancing the fast-charging capability of the cell.

Ball Milling and Screening

The graphitized material is vacuum-conveyed into a ball mill for physical mixing and ball milling. The material is then screened. The screened product is inspected, measured, and packaged. The oversize particles undergo secondary ball milling, after which they are inspected, measured, and packaged.

Pollutants mainly include particulate matter, sulfur dioxide, nitrogen oxides, asphalt fumes, and small amounts of benzo(a)pyrene. Particulate matter is mainly treated using a baghouse dust collector. Sulfur dioxide and nitrogen oxides are primarily treated using the double-alkali desulfurization method. Asphalt fumes and benzo(a)pyrene are mainly treated through collection and adsorption.

Epic powder

Epic Powder, 20+ years of work experience in the ultrafine powder industry. Actively promote the future development of ultra-fine powder, focusing on crushing, grinding, classifying and modification process of ultra-fine powder. Contact us for a free consultation and customized solutions! Our expert team is dedicated to providing high-quality products and services to maximize the value of your powder processing. Epic Powder—Your Trusted Powder Processing Expert !