Microspheres refer to spherical particles with a size range from micro to nano, and they are widely used as composite materials. They have attracted significant attention due to their large specific surface area, stable mechanical structure, modifiability, and strong adsorption capacity. Among them, silica microspheres have become one of the most mature and widely used materials in research. Silica microspheres feature a large specific surface area, low dielectric constant, low expansion coefficient, and strong adsorption. They also exhibit excellent chemical stability, thermal shock resistance, and easy dispersion, making them stand out among other types of microspheres.

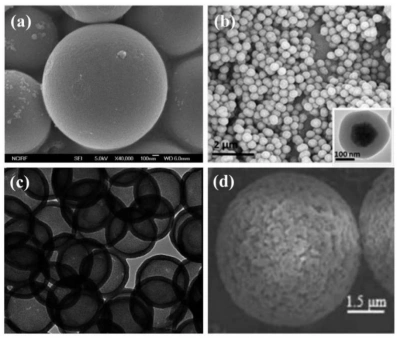

Based on the structural characteristics of SiO2 microspheres, they can be classified into four types: non-porous microspheres, core-shell microspheres, hollow microspheres, and porous microspheres.

- Non-porous microspheres have a completely solid, non-porous structure.

- Hollow microspheres have a cavity structure at the center.

- Core-shell microspheres consist of a solid core inside and a porous shell outside.

- Porous microspheres have numerous pores on the surface or within the microsphere.

Since SiO2 microspheres have varying structures, their preparation methods are also diverse, including: spray drying, sol-gel method, hard template method, soft template method, gas-phase method, microemulsion method, chemical deposition method, emulsion polymerization method, hydrothermal method, and others.

(a) Solid structure (b) Core-shell structure (c) Hollow structure (d) Porous structure

Non-porous microspheres

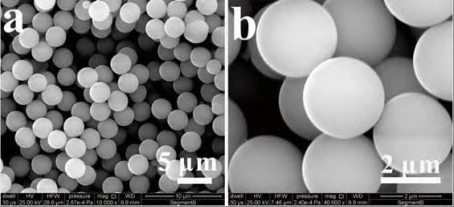

Nonporous silica microspheres have good chemical stability, hydrophilicity and modifiability. Therefore, they are widely used in harmaceuticals delivery, biological detection, catalysis, optical materials and other fields. In addition, they have a large specific surface area and good dispersibility, which are suitable for a variety of scientific research and industrial applications.

Nonporous silica microspheres can be prepared by sol-gel method and other methods. When preparing solid microspheres, tetraethyl orthosilicate (TEOS) is mainly used as the silicon source. Under the action of acid or alkali, the silicon source undergoes hydrolysis and condensation reaction. The condensation product produced grows into spherical particles under the action of surface tension. Therefore, there are two main reasons for the formation of pores in the prepared microspheres. One is that TEOS is not completely hydrolyzed, and there is residual organic carbon, which forms pores after high-temperature burning. The second is that Si-OH fails to fully complete the condensation reaction. Then, pores are generated, and the pore size is small, which is considered to be solid microspheres.

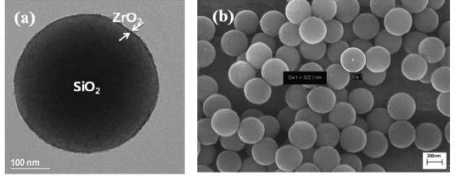

Core-shell microspheres

Core-shell silica microspheres are characterized by high efficiency, rapidity and low back pressure. They are often used in chromatographic rapid separation and analysis techniques.

Core-shell microspheres can be prepared by combining the sol-gel method with the template method.

Hollow microspheres

Hollow silica has a cavity structure inside. It is non-toxic, has a high melting point and stability, and is easy to modify. Therefore, it has many applications in drug-controlled release, refractory materials, capsule encapsulation, nanocatalysts, and more.

Hollow silica microspheres are primarily prepared by the template method. When using the template method to prepare hollow microspheres, the process usually includes the following steps:

- Prepare and functionalize the template.

- Use physical or chemical methods to coat the template.

- Remove the template.

Depending on the type of template selected in the microsphere preparation process, as well as its functional characteristics and removal method, the template method can be classified into three types: the hard template method, soft template method, and sacrificial template method.

Porous microspheres

Porous SiO2 microspheres have excellent properties, such as non-toxicity, high-temperature resistance, stable physical and chemical properties, a large specific surface area, controllable particle and pore sizes, and easy surface modification. These characteristics make them valuable for applications in catalysis, high-performance liquid chromatography, biomedicine, biosensors, and cosmetics.

The International Union of Pure and Applied Chemistry (IUPAC) classifies porous materials based on pore size. Pores smaller than 2 nm are called micropores. Pores between 2 and 50 nm are called mesopores, and pores larger than 50 nm are called macropores.

Porous SiO2 microspheres are fully porous structures. They include microporous, mesoporous, and macroporous SiO2 microspheres.

The main preparation methods for these microspheres include the template method based on the sol-gel method, and the polymerization-induced colloidal aggregation method (PICA).

When using the template method, high production costs and complex reactions limit its industrial application. The reaction process is difficult to control, and repeatability is low.

conclusion

Silica microspheres have become important functional materials due to their unique structure and excellent performance. They have four main structures: non-porous, core-shell, hollow, and porous. Each structure has its own preparation characteristics and application value.

Although some preparation methods have cost or process limitations, silica microspheres continue to drive the innovative development of materials science. They also play a significant role in interdisciplinary fields, thanks to their designable structures and functions.

Epic powder

Epic Powder, 20+ years of work experience in the ultrafine powder industry. Actively promote the future development of ultra-fine powder, focusing on crushing, grinding, classifying and modification process of ultra-fine powder. Contact us for a free consultation and customized solutions! Our expert team is dedicated to providing high-quality products and services to maximize the value of your powder processing. Epic Powder—Your Trusted Powder Processing Expert !