Kaolin deep processing refers to a series of treatments applied to kaolin to improve its quality, performance, and added value, meeting the specific requirements of various industries.

The main kaolin deep processing technologies include the following:

Purification and Whitening Technology

Physical Purification: Separates non-clay minerals based on differences in particle size, density, magnetism, and surface adsorption properties. Methods include hand sorting, water selection, flotation, and magnetic separation.

Chemical Purification and Bleaching: Primarily removes iron-bearing minerals from kaolin. Common methods include acid leaching, chlorination, alkaline treatment, reduction, oxidation, and combined oxidation-reduction methods.

High-Temperature Calcination: This is the best method for carbon removal and whitening, especially for coal-based kaolin. Calcination at 650-1050°C transforms the kaolin phase, volatilizes impurities, and improves whiteness and insulation properties. Chloride roasting or oxidative roasting can be used to remove iron and titanium elements from kaolin.

Ultrafine Processing Technology

Mechanical Pulverization:

Utilizes the layered structure of minerals, breaking the force between layers under external pressure to achieve ultrafine particle size. This method consumes a lot of energy. Kaolin ultrafine grinding is divided into dry, wet, dry-wet hybrid, and nanotechnology methods. Dry processing is suited for hard kaolin; wet fine grinding is mainly used for soft and sandy kaolin after sand removal, commonly used in coating-grade kaolin products.

Classification:

Follows Stokes’ law to classify kaolin in liquids to obtain ultrafine kaolin. However, the process is costly and has low yield.

Intercalation-Exfoliation:

Uses intercalation to expand the mineral layers, weakening the bond force. After removing the intercalating substance, the kaolinite naturally splits into smaller sheet-like particles, achieving natural exfoliation.

Chemical Synthesis:

Typically uses rock minerals or aluminum-silicon gels as raw materials in hydrothermal synthesis to produce ultrafine synthetic kaolinite. It has high purity, good suspension stability, excellent light scattering, and other superior properties.

Kaolin Calcination Process

By Process Flow

Grind First, Then Calcine:

The raw ore is dry-ground, then finely ground in wet form, dried, dispersed, calcined, and re-dispersed and classified to obtain the product. This process results in high whiteness, thorough calcination of micron-sized particles, and iron reduction using whitening agents during calcination. However, it requires more equipment. Fine particles may stick or sinter after calcination, possibly requiring further ultrafine grinding and drying.

Calcine First, Then Grind:

The raw ore is crushed and calcined before being finely ground. This process ensures that the particle size is within specification with a simpler process. However calcining first increases hardness and ball consumption. As a result, whiteness is 1-3% lower compared to the first method.

By Calcination Temperature

Low-Temperature Calcination: At temperatures of 500-700°C, it removes hydroxyl groups and is used as a filler for cable plastics and rubber seals.

Medium-Temperature Calcination: At temperatures of 925-1000°C, it can substitute TiO₂ and is used as a filler for paper.

High-Temperature Calcination: At temperatures of 1300-1525°C, it can be used as a filler for refractory products or the inner lining of optical glass crucibles.

Modification Technology

Acid-Base Modification: This process activates kaolin by calcining it at specific temperatures, allowing the aluminum and silicon to react with acids or bases, changing their acidity, pore size, and specific surface area.

Surface Modification: This involves using physical, chemical, or mechanical methods to treat the surface of kaolin to alter its physicochemical properties, improving whiteness, brightness, chemical activity, and compatibility with polymers.

Intercalation Modification: Involves inserting organic molecules into the interlayer of kaolinite without damaging its original layered structure.

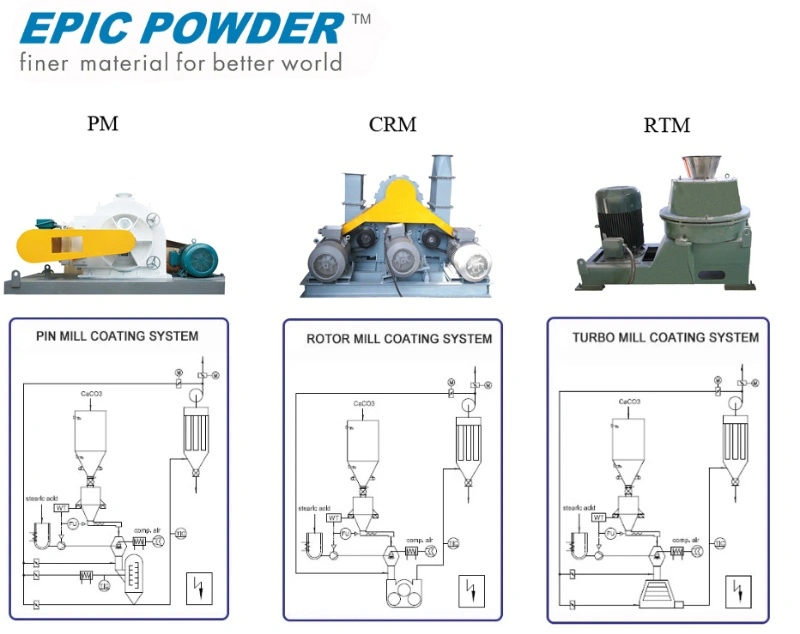

Epic powder

Epic Powder’s advanced grinding equipment plays a vital role in the deep processing of kaolin, particularly in ultrafine grinding and surface modification. By utilizing cutting-edge technologies such as ball mills, air classifiers, and surface modification systems, Epic Powder helps to produce kaolin products that meet high-quality standards. As the demand for high-performance materials grows, Epic Powder’s expertise in kaolin processing will be crucial in ensuring efficient, cost-effective production for various industrial applications, including fillers for plastics, coatings, and other high-tech uses.