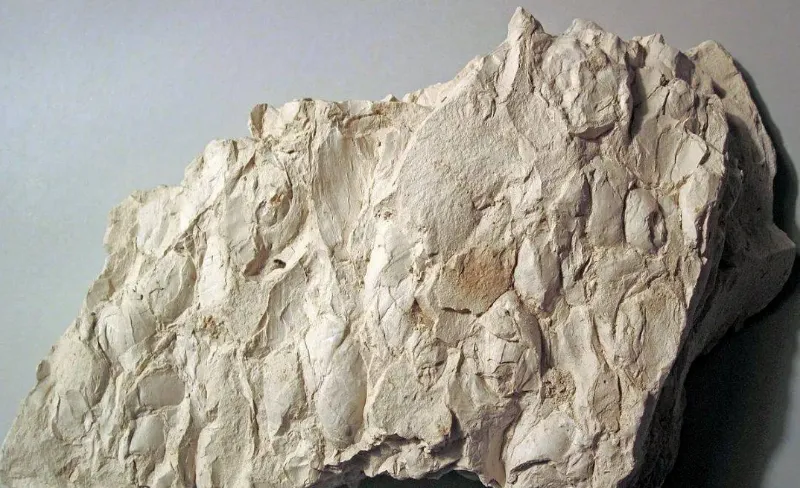

Diatomaceous earth is formed from the silica remains of a type of single-celled algae known as diatoms, which die and leave behind their silica skeletons. Its essence is hydrous amorphous SiO₂. Diatomite is a type of siliceous rock and a biologically formed siliceous sedimentary rock. It appears in various shapes, including disc-like, sieve-like, tubular, and straight rod-like. The silica surface is covered with numerous orderly arranged micropores.

Pure diatomaceous earth is generally white and composed of opal and its variants. It is often contaminated by iron oxide or organic matter, turning it grayish-white, light yellow, gray, or black. The streak is white. It has a soil-like luster, no cleavage, is lightweight, porous, and brittle. However, the hardness of diatom particles can reach 4.5-5, and its density varies depending on impurity content. It features strong adsorption capacity, low thermal conductivity, and good chemical stability.

The main chemical component of diatomite is SiO₂, which typically constitutes over 80%, reaching up to 94%, and exists in the form of SiO₂·nH₂O. It also contains small amounts of Al₂O₃, Fe₂O₃, CaO, MgO, K₂O, Na₂O, P₂O₅, and organic matter. In some cases, it may contain metallic impurities like Cr and Ba. Its mineral composition includes opal and its variants, as well as clay minerals, quartz, feldspar, dolomite, and others.

Basic Properties of Diatomaceous Earth

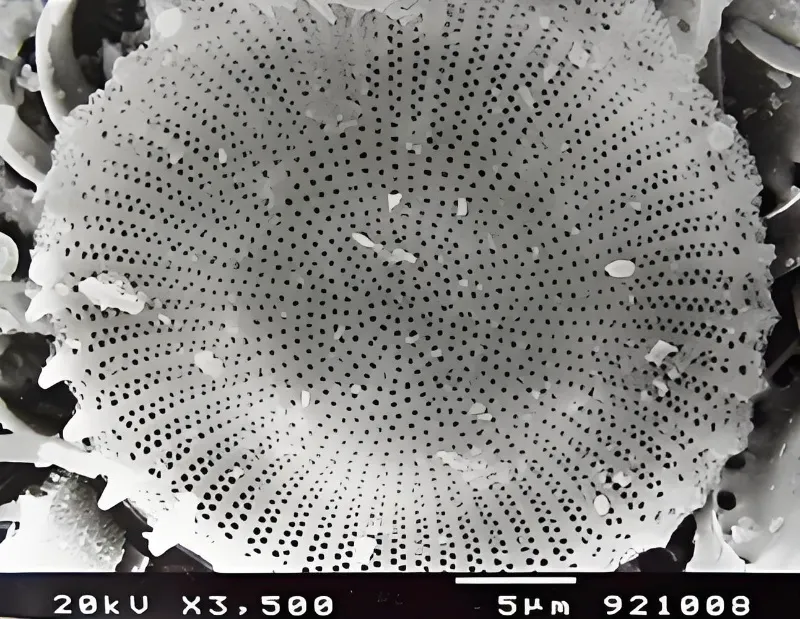

The wide application value of diatomaceous earth largely comes from its unique microporous structure. This structure gives diatomaceous earth a high porosity and specific surface area, which grants excellent adsorption, filtration, and thermal insulation properties.

- Microporous Structure: The microporous structure is formed by the cell walls and intercellular spaces of the diatom remains. These pores vary in size and shape but collectively provide a large internal space.

- High Porosity: Due to its numerous micropores, diatomaceous earth has a high porosity, allowing it to absorb large amounts of liquids or gases.

- Large Specific Surface Area: High porosity leads to a large specific surface area. This means that the surface area per unit mass or volume is vast, which enhances its adsorption and filtration efficiency.

- Chemical Stability: The main chemical composition, SiO₂, does not react with most acids or bases under normal conditions (except for hydrofluoric acid). This gives diatomaceous earth excellent chemical stability, maintaining its structure and properties in various environments.

Applications of diatomite

Diatomaceous earth is an excellent lightweight thermal insulation material with low thermal conductivity. It is used in boilers, distillers, heat treatment furnaces, dryers, and lightweight insulation boards, as well as in calcium silicate insulation materials, diatomaceous earth bricks, and other insulation products. Additionally, it is used as a filler in fiberglass, rubber, plastics, paper, coatings, pesticides, and compound fertilizers, improving the performance and quality of these products. For example, adding diatomaceous earth to coatings reduces the surface gloss of the film and increases its abrasion resistance and scratch resistance. Furthermore, it serves as a filtration aid, functional filler, construction material, and in environmental technology.

Conclusion

Diatomaceous earth, a naturally formed lightweight siliceous sedimentary rock, showcases excellent performance in terms of lightness, low thermal conductivity, and significant heat resistance. It plays a crucial role as an efficient energy-saving thermal insulation material in high-temperature environments across industries like metallurgy, chemicals, and construction. It also has notable applications in environmental filtration and functional fillers. Its natural origins, superior properties, and environmental friendliness make it an irreplaceable material in modern industrial technology and sustainable development. The potential and application prospects of diatomite deserve continued attention and in-depth exploration.

Epic powder

Epic Powder, 20+ years of work experience in the ultrafine powder industry. Actively promote the future development of ultra-fine powder, focusing on crushing, grinding, classifying and modification process of ultra-fine powder. Contact us for a free consultation and customized solutions! Our expert team is dedicated to providing high-quality products and services to maximize the value of your powder processing. Epic Powder—Your Trusted Powder Processing Expert !