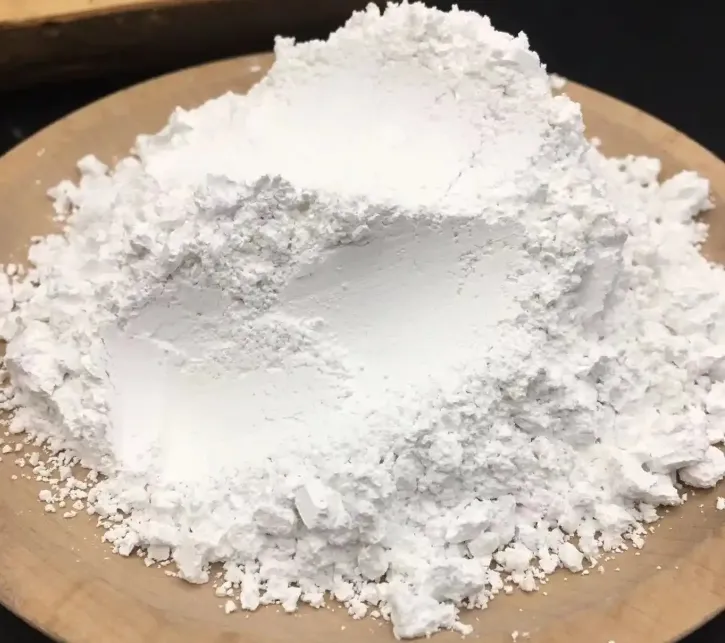

Understanding heavy calcium carbonate (CaCO₃) requires analyzing its natural and industrial traits. This mineral powder is widely used globally. Its raw materials are abundant and low-cost. Key advantages include high whiteness and low oil absorption. These properties ensure broad applicability.

Heavy calcium carbonate is vital in papermaking, plastics, and coatings. It acts as a filler, stabilizer, and gloss enhancer. Recent studies focus on its microscopic features. Particle size and surface treatments drive innovation.

Modified heavy calcium enhances biodegradable materials. It also reduces carbon footprints in construction. Industries now prioritize such sustainable solutions. Balancing cost and eco-friendliness remains a challenge.

Definition of Heavy Calcium Carbonate

Heavy calcium carbonate powder is a product made from natural materials such as calcite, marble, dolomite, or chalk. It is processed through grinding and classification to achieve a certain fineness, typically referred to as GCC. The sedimentation volume of mechanically ground calcium carbonate (1.1–1.9 mL/g) is lower than that of light calcium carbonate (2.4–2.8 mL/g).

Heavy calcium carbonate is also known as:

- Single-fly powder

- Water-ground terrazzo powder

- Double-fly powder

- Triple-fly powder

- Quadruple-fly powder

- Limestone powder

- Chalk powder

- White powder

- Natural calcium carbonate

Mineral Raw Materials

| Carbonate minerals | Characteristics |

| Limestone | Hardness: 3, Density: 2.6-2.9, Melting point: 825°C. Decomposes into calcium oxide and carbon dioxide between 830-1020°C. Reacts with dilute acids, producing effervescence and dissolving. |

| Calcite | Hardness: 2.704–3.0, Specific gravity: 2.6–2.8 g/cm³, Melting point: 1339°C. Decomposes into CaO and CO₂ between 830-1020°C. Reacts with dilute acids, releasing CO₂ in an exothermic reaction. Almost insoluble in water, dissolves in chloride solutions. |

| Marble | Recrystallized limestone, primarily composed of calcite, serpentine, and dolomite. Hardness: 3.5–4.0, Brittle, pure marble known as “Han White Marble.” |

| Chalk | A variety of calcite, Hardness: 3, Density: 2.93 g/cm³, Brittle. Perfect cleavage, shell-like fracture. Almost insoluble in water but dissolves in water containing ammonium salts or ferric oxide. Insoluble in alcohol, no reaction in the air. |

| Dolomite | Crystal structure similar to calcite, usually in rhombohedral form. Hardness: 3–4, Density: 2.86–3.20 g/cm³, Reacts with cold dilute hydrochloric acid, producing effervescence. |

Heavy calcium carbonate classification

Classification by particle size:

Micronized Calcium Carbonate :Particle size greater than 5μm, typically used as a brightener.

Ultrafine Calcium Carbonate :Particle size below 0.02μm, exhibits transparency or translucency.

Fine Calcium Carbonate :Particle size between 0.1μm and 1μm.

Ultrafine Calcium Carbonate :Particle size between 0.02μm and 0.1μm.

Classification by surface treatment agent

Activated Calcium Carbonate

Activated calcium carbonate, also known as active calcium carbonate, is treated with activators. Common activators include organic compounds with non-polar, oleophilic groups such as stearic acid, linoleic acid, rosin acid, and lignosulfonic acid.

Coupling Agent-Treated Calcium Carbonate

Coupling agents act as “bridges” between inorganic materials and polymer materials at their interface. Commonly used coupling agents include:

- Phosphate ester coupling agents

- Aluminum ester coupling agents

- Titanium ester coupling agents

- Boric acid ester coupling agents

- Silane-based coupling agents

- Phthalate ester coupling agents

Calcium carbonate deep processing technology

Dry process :Ore dressing–Coarse crushing–Fine crushing–Grinding–Classification–Collection–Testing–Packaging.

Raw ore–cleaning and screening–crushing–dry grinding–classification and collection–slurry preparation–wet grinding–vibration screening–drying and collection–finished product.

The main dry process equipment includes: Raymond mill, dry stirred mill, ball mill, vibration mill, ring roller mill and vertical mill.

Modification of heavy calcium carbonate

Modification Objectives

- Reduce the surface energy of heavy calcium carbonate to prevent aggregation.

- Improve the dispersion of heavy calcium carbonate in the matrix.

- Enhance the interface affinity between the surface of heavy calcium carbonate and the matrix.

- Improve the specificity and functionality of modified heavy calcium carbonate.

Modification Methods

- Physical Coating Modification

- Mechanical Force Chemical Modification

- High-Energy Surface Modification

- Surface Chemical Modification

- Surface Deposition Modification

Surface Chemical Modification Processes and Principles

- Coupling Agent Modification

- Composite Coupling Agent Modification

- Polymer Coating Modification

- Organic Compound Modification

Conclusion

In conclusion, heavy calcium carbonate exemplifies how a naturally abundant mineral can drive industrial innovation. Its cost-effectiveness and adaptable properties make it irreplaceable in traditional sectors like paper and plastics. Yet, deeper understanding heavy calcium carbonate —through nanotechnology and eco-friendly processing—is reshaping its role in a circular economy. As industries strive for carbon neutrality, this mineral’s potential in green materials and waste reduction will only expand. The future lies not just in using it, but in redefining its value chain through science and sustainability.

Epic powder

Epic Powder, 20+ years of work experience in the ultrafine powder industry. Actively promote the future development of ultra-fine powder, focusing on crushing,grinding,classifying and modification process of ultra-fine powder. Contact us for a free consultation and customized solutions! Our expert team is dedicated to providing high-quality products and services to maximize the value of your powder processing. Epic Powder—Your Trusted Powder Processing Expert !