With the increasing global consumption of coffee, a large amount of coffee grounds is generated as waste. According to statistics, approximately 60 million tons of coffee grounds are discarded each year worldwide. This not only leads to environmental pollution but also wastes its potential resources. However, recent research has shown that waste coffee grounds have significant potential, especially in the preparation of highly porous carbon materials, which exhibit ideal characteristics.

Composition of Coffee Grounds

Coffee grounds are mainly composed of organic and inorganic materials, including cellulose, hemicellulose, lignin, and a certain amount of minerals. The rich organic content makes coffee grounds an ideal base material for the preparation of highly porous carbon. Among the organic components, cellulose and lignin are crucial for the creation of porous carbon materials.

Applications of Porous Carbon Materials

With the increasing global consumption of coffee, a large amount of coffee grounds is generated as waste. Approximately 60 million tons of coffee grounds are discarded each year worldwide. This leads to environmental pollution and wastes potential resources. However, recent research has shown that waste coffee grounds have significant potential. They are particularly valuable in the preparation of highly porous carbon materials, which exhibit ideal characteristics.

Composition of Coffee Grounds

Coffee grounds consist of organic and inorganic materials. These include cellulose, hemicellulose, lignin, and some minerals. The rich organic content makes coffee grounds an ideal base for porous carbon. Cellulose and lignin are crucial for the creation of porous carbon materials.

Applications of Porous Carbon Materials

Porous carbon materials have high surface area, large pore volume, and excellent adjustability. They are used in adsorption, catalysis, energy storage, and water treatment. Due to their unique structure, highly porous carbons exhibit excellent adsorption properties. They can effectively adsorb harmful substances, such as heavy metal ions and organic pollutants. Furthermore, porous carbon materials are widely used in supercapacitors, batteries, and fuel cells. They improve storage capacity and charge-discharge efficiency due to their electrical conductivity and high surface area.

Advantages of Using Waste Coffee Grounds for highly Porous Carbon Preparation

Using waste coffee grounds as a raw material helps reduce environmental pollution. It also provides a low-cost source of carbon materials. One of the main advantages is its environmental friendliness. Traditional porous carbon methods require expensive chemicals and energy-intensive processes. Using waste coffee grounds lowers production costs and reduces environmental burdens.

Moreover, coffee grounds are widely available, especially in coffee-consuming areas. Treating and utilizing waste coffee grounds is an important direction for resource recovery. By employing proper treatment, waste coffee grounds can be transformed into valuable industrial raw material.

Preparation Process

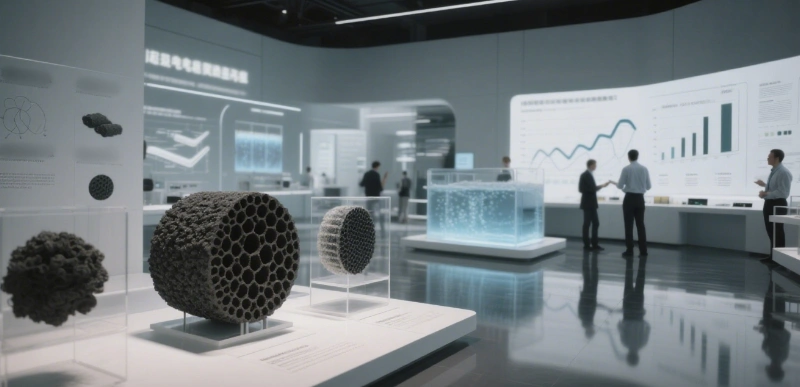

The preparation process of highly porous carbon from waste coffee grounds includes several steps:

- Pre-treatment: Coffee grounds are cleaned and dried to remove moisture and impurities. This improves the final product’s quality.

- Carbonization: The cleaned coffee grounds are placed in a furnace. They are heated at high temperatures (between 400°C and 800°C) in an oxygen-limited environment. Organic components decompose, forming a porous carbon structure.

- Activation: After carbonization, the coffee grounds undergo chemical or physical activation. This increases their surface area and pore volume. Common chemical activators include zinc chloride and potassium hydroxide. Physical activation uses steam or carbon dioxide.

Through this method, waste coffee grounds become porous carbon materials with high surface area and excellent pore structure, suitable for various applications.

Application Prospects

With growing environmental awareness, waste coffee grounds are being recognized as a valuable source for porous carbon materials. These materials are useful in environmental protection fields, such as wastewater treatment and air purification. They are also widely applied in energy storage, such as supercapacitors and lithium batteries. Coffee grounds can serve as catalyst supports, gas adsorbents, and molecular sieves.

In the future, with improved technologies and reduced costs, highly porous carbon from waste coffee grounds will see wider use and play an important role in many industries.

Conclusion

Waste coffee grounds are an inexpensive, environmentally friendly, and abundant raw material. They have great potential for preparing porous carbon materials. By using appropriate processing methods, waste coffee grounds can be transformed into high-performance porous carbon. These materials are applied in adsorption, catalysis, energy storage, and other fields. With ongoing technological advancements, waste coffee grounds will become a valuable resource for both environmental sustainability and the green economy.

epic powder

Epic Powder, 20+ years of work experience in the ultrafine powder industry. Actively promote the future development of ultra-fine powder, focusing on crushing, grinding, classifying and modification process of ultra-fine powder. Contact us for a free consultation and customized solutions! Our expert team is dedicated to providing high-quality products and services to maximize the value of your powder processing. Epic Powder—Your Trusted Powder Processing Expert !