The ceramic lined air jet mill utilizes the self-grinding principle to achieve ultrafine grinding of materials using high-speed airflow. Its grinding chamber minimizes product contamination, producing particles with smooth surfaces, regular shapes, and good dispersion. Typically, grinding media are made from metal, which can introduce impurities when crushing harder materials or at high speeds. However, the ceramic lining reduces wear and metal contamination, ensuring a cleaner product. The ceramic liners also enhance wear resistance, reduce material impact, and extend the mill’s service life. This design controls iron content during grinding and classification, addressing issues like adhesion, insufficient fineness, and uneven classification, especially for battery materials.

Features of ceramic lined air jet mill

Advanced ceramic materials offer wear resistance, corrosion resistance, high-temperature tolerance, and reduced contamination. By designing the most suitable lining based on the specific characteristics of the materials being processed (such as hardness, corrosiveness, temperature requirements, etc.), it not only improves grinding efficiency, extends equipment lifespan, and reduces maintenance costs, but also ensures high-quality product output. These ceramics are particularly suitable for industries such as chemicals, mining, pharmaceuticals, and food. Key functions and features include:

- The lining material can be customized according to customer requirements.

- No temperature rise: Since materials are crushed in an expanded gas state, the grinding chamber temperature is maintained at room temperature and does not increase.

- No contamination: Materials are crushed through self-collision driven by airflow, without the introduction of grinding media, preventing contamination during the process.

- Low wear: The main crushing mechanism involves particle-to-particle impact, with minimal contact between high-speed particles and the chamber wall, making it suitable for crushing materials with a Mohs hardness of 9 or higher.

- Low energy consumption: Compared to other types of air jet mills, energy consumption is reduced by 30%-40%.

- For flammable and explosive materials, inert gases can be used as the crushing medium.

- Advanced automation control ensures real-time monitoring of operating status. The PLC software can be upgraded, and with standardized internet technology, real-time monitoring and remote control are available, offering excellent maintainability.

Conclusion

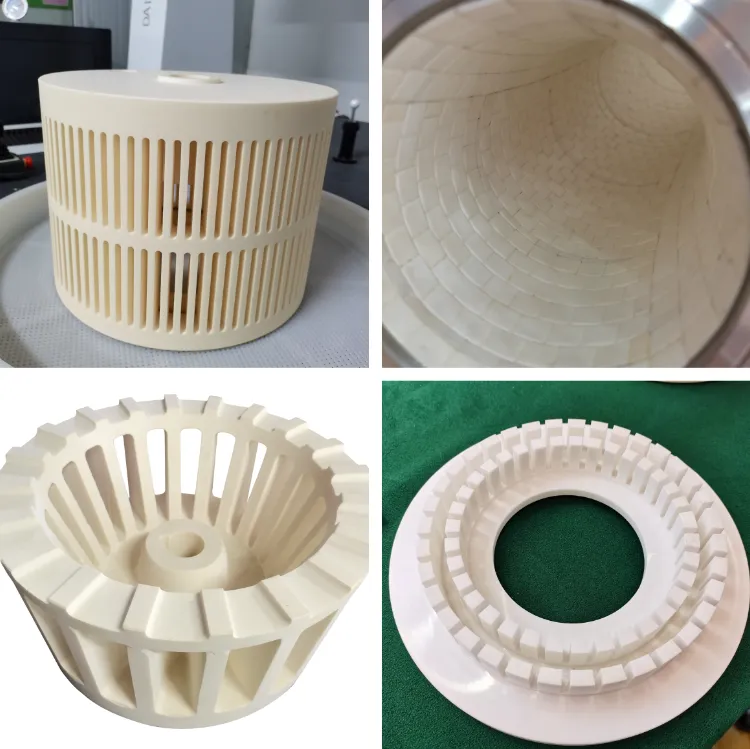

The ceramic lined air jet mill from Epic Powder is a “true all-ceramic” machine, with all components, including the lining, feeding mechanism, nozzle, and grading wheel, made from 99% alumina or zirconia ceramics. This design fully protects impact and overcurrent parts, preventing metal contamination during airflow crushing. The high hardness and wear resistance of the ceramic module minimize wear and foreign matter introduction, making it ideal for high-purity materials and non-mining industries. It meets the demands for larger production capacity, reduced pollution, and increased product value during industry upgrades.

Contact us for a free consultation and customized solutions! Our expert team is dedicated to providing high-quality products and services to maximize the value of your powder processing. Epic Powder—Your Trusted Powder Processing Expert !