Polypropylene (PP), widely used as a thermoplastic polymer, is known for its easy processing and excellent properties. It plays a key role in packaging, home appliances, automotive parts, and many other fields. However, PP still has limitations, including high thermal shrinkage, poor performance at low temperatures, and low impact resistance. Polypropylene modified mineral powders are commonly used to enhance the mechanical properties of PP in various applications. The goal is to enhance performance and expand its applicability in various scenarios.

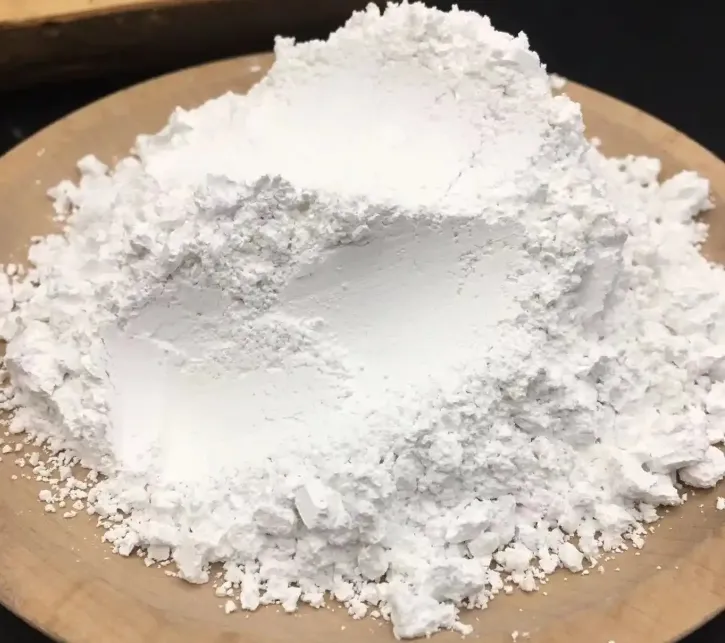

Calcium carbonate

Polypropylene modified mineral powders-calcium carbonate, due to its abundant resources, variety, non-toxicity, and ease of processing, has a wide range of applications in synthetic resin filling, especially in polypropylene (PP) fillers. Calcium carbonate is primarily divided into three types: nano-calcium carbonate, heavy calcium carbonate, and light calcium carbonate. These different types of calcium carbonate powders, based on their specific physical and chemical properties, each demonstrate unique performance impacts in polypropylene modification fillers.

talcum powder

Polypropylene modified mineral powders-talc powder, a natural mineral rich in magnesium silicate, has a unique layered structure, good insulation properties, and stability. It is widely used in polypropylene (PP) applications. Talc can significantly reduce the shrinkage rate of PP materials and, to some extent, improve the tensile modulus, enhancing its mechanical properties and stability.

Mica

Mica, with its unique physical and chemical properties, plays an important role in industries such as insulation materials, plastics, rubber, paper, and paints. Mica has a special large aspect ratio structure, which enhances plastic products. It can improve the physical properties of plastic items such as mechanical components, vehicle parts, plastic wood products, appliance housings, packaging materials, films, fibers, and ropes.

Silicon dioxide

Silica powder, as a widely used inorganic material, is favored for its high purity, regular shape, and various preparation methods. In particular, nano-silica, with its unique three-dimensional network structure and large specific surface area, can effectively improve the overall performance of composite materials when applied to polymers.

Kaolin

Kaolin, primarily composed of kaolinite clay minerals, is a powder formed from feldspar, common pyroxene, and other aluminosilicate minerals during weathering. This powder typically appears matte, and when pure, it is white and finely textured, with plasticity, adhesiveness, and volume expansion properties. Kaolin can enhance the tensile strength and modulus of thermoplastic materials, improving the rigidity and strength of plastic products. When added to polypropylene, it can also act as a nucleating agent. After calcination, kaolin significantly improves the electrical insulation strength of plastics, making it suitable for wires, cables, and high-voltage insulation products. Kaolin has a remarkable infrared blocking effect and has been applied in military equipment; in films, it improves thermal insulation performance.

Wollastonite

Wollastonite can be widely used in PET, PA, PE, PP, ABS resins. Many of its properties are similar to talc, mica, and other inorganic powders. As a new inorganic modifier in plastics, processing should maintain a large aspect ratio of its rod-like structure. Surface activation modification using silane coupling agents improves the interface compatibility of different materials. Wollastonite improves the heat distortion temperature of resins. It mitigates strength and modulus loss in resins with high water absorption in humid environments. Physical properties improve significantly depending on the type of resin.

Barium sulfate

Barium sulfate (BaSO4) is divided into two types: natural barium sulfate (barite powder) and synthetic barium sulfate. The specific surface area of synthetic barium sulfate ranges from 22,000 to 140,000 cm²/g. As a plastic filler, it smooths the product surface and provides good gloss. Barium sulfate has excellent properties, including chemical stability, scratch resistance, heat resistance, and refractive index. It disperses easily and provides better sound insulation, thermal insulation, and gloss than many inorganic powders. It is widely used in appliance shells, masterbatches, films, pipes, profiles, etc. However, the specific gravity of barium sulfate is a key factor affecting its performance.

Conclusion

There are many types of inorganic powders, and the application technologies of these powders in PP modification are relatively mature. Especially with the rich downstream application scenarios, the performance requirements for PP may vary. Inorganic powders with diverse properties can provide more options for targeted filling modification.

epic powder

Epic Powder, 20+ years of work experience in the ultrafine powder industry. Actively promote the future development of ultra-fine powder, focusing on crushing,grinding,classifying and modification process of ultra-fine powder. Contact us for a free consultation and customized solutions! Our expert team is dedicated to providing high-quality products and services to maximize the value of your powder processing. Epic Powder—Your Trusted Powder Processing Expert !