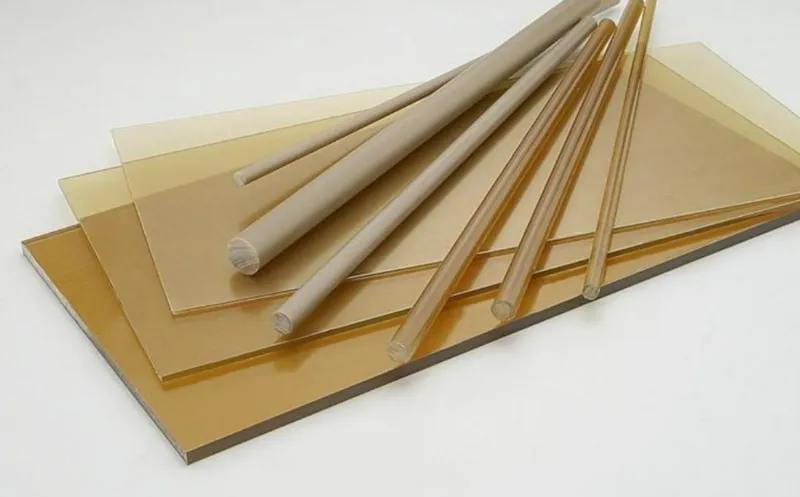

Polyetheretherketone (PEEK) is a special engineering plastic. It was first developed by Imperial Chemical Industries (UK) in 1978. In the field of engineering plastics, PEEK is at the very top of the pyramid. It has comprehensive and outstanding performance. It can rival ordinary metals and outperforms most plastics. When compared with metals, PEEK stands out with excellent properties.

It has become a key material for the lightweight concept of “replacing steel with plastic.” PEEK Micropowder is created through advanced grinding processes, where technologies such as the jet mill for Polyetheretherketone play a crucial role. By reducing PEEK resin into ultrafine, uniform particles, jet milling ensures the powder retains PEEK’s superior characteristics—high-temperature resistance, chemical corrosion resistance, mechanical strength, and excellent biocompatibility. This makes PEEK micropowder an ideal choice for aerospace, medical, electronics, and other high-end applications.

A critical Role of Jet Mill for polyetheretherketone (PEEK) Preparation

1. Raw material refinement:

Jet milling reduces PEEK powder to D50 < 10 μm. This improves fiber impregnation efficiency during melt infiltration. Studies show that uniform particle distribution reduces composite porosity by over 30%.

2. Nanocomposite modification:

Jet milling disperses nano-reinforcements (such as nanodiamonds) at the submicron level. This provides super-lubrication with friction coefficients as low as 0.03. Such materials are ideal for precision medical devices like interventional catheters.

3. Process optimization:

- Temperature-pressure synergy: Jet mill pretreatment combined with hot pressing lowers forming temperatures by 20–30°C (down to ~350°C).

This reduces resin thermal degradation risks. - Functional modification: Jet milling grafting introduces active groups (e.g., heparin molecules) onto PEEK surfaces. This imparts anticoagulant properties and reduces thrombosis risk by 40%.

Application Fields of polyetheretherketone(PEEK)

- 3D Printing Materials

PEEK micropowder can be used in 3D printing, particularly for the manufacture of high-performance, high-temperature-resistant components, such as complex structural parts in the aerospace, automotive, and medical sectors. 3D printing technology enables personalized customization and rapid prototyping. - Composite Material Reinforcement

Combining PEEK micropowder with other matrix materials (such as resins and metals) can improve the material’s mechanical properties, heat resistance, and wear resistance. For example, it is used in automotive parts and electronic device casings to enhance the overall performance of the material. - Pharmaceuticals Devices

Due to its biocompatibility, PEEK micropowder can be used in the manufacture of pharmaceuticals devices such as artificial joints, spinal implants, and dental restorations, reducing the body’s immune response and promoting tissue healing. - Electrical and Electronic Insulation Materials

PEEK micropowder’s high insulating properties make it suitable for the manufacture of insulating components for electronic devices, such as wires and cables, circuit boards, and connectors, ensuring stable operation in harsh environments such as high temperature and high humidity. 5. Aerospace Components

In the aerospace sector, PEEK micropowder can be used to manufacture aircraft engine components, wing structures, satellite parts, and more, reducing weight while improving high-temperature and corrosion resistance. - Energy Sector

In energy sectors such as the nuclear industry and oil and gas extraction, PEEK micropowder can be used to manufacture radiation-resistant and high-temperature-resistant seals, pipes, and valves, meeting performance requirements under extreme operating conditions. - Research and Experimental Materials

PEEK micropowder is frequently used in materials science research and experiments to explore its performance under various environments and provide fundamental data for the development of new materials.

Due to its unique properties, PEEK micropowder plays an important role in multiple high-end manufacturing fields, offering irreplaceable advantages in applications requiring extremely high material performance.

Epic powder

With over 20 years of expertise in ultrafine grinding, Epic Powder’s jet mill solutions provide precise control over PEEK micropowder preparation. By ensuring uniform particle size and excellent dispersion, Epic Powder empowers industries to unlock the full potential of PEEK in aerospace, medical, and advanced manufacturing applications.